With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Blue Ribbon Fastener, we specialize in providing high-quality bolts and fastening solutions tailored to meet the demands of various industries. With a commitment to precision, reliability, and durability, we ensure that our products exceed performance expectations in even the most challenging applications. Our extensive selection includes a wide range of bolts, each manufactured to exact...

Delta Fastener Corp. supplies headed fasteners from only quality manufacturers. Our huge, readily available selection includes industrial bolts, nuts, washers, screws, etc. in a wide range of metal types and grades. Check out our online catalog or give us a call today for industrial bolts and more!

P&R is a manufacturer of industrial fasteners, specialty fasteners, automotive fasteners, stainless steel fasteners, aerospace and electronic fasteners. We provide over 60 years of experience in designing quality industrial fastener products. Give us a call so we can work together.

Chicago Nut & Bolt specializes in nonstandard products such as industrial bolts, stainless steel bolts, carriage bolts, titanium bolts, mil spec bolts and alloy bolts in any quantity. We will supply any shape or size depending on your requirements. We assure quality products and on-time delivery.

More Lag Bolt Manufacturers

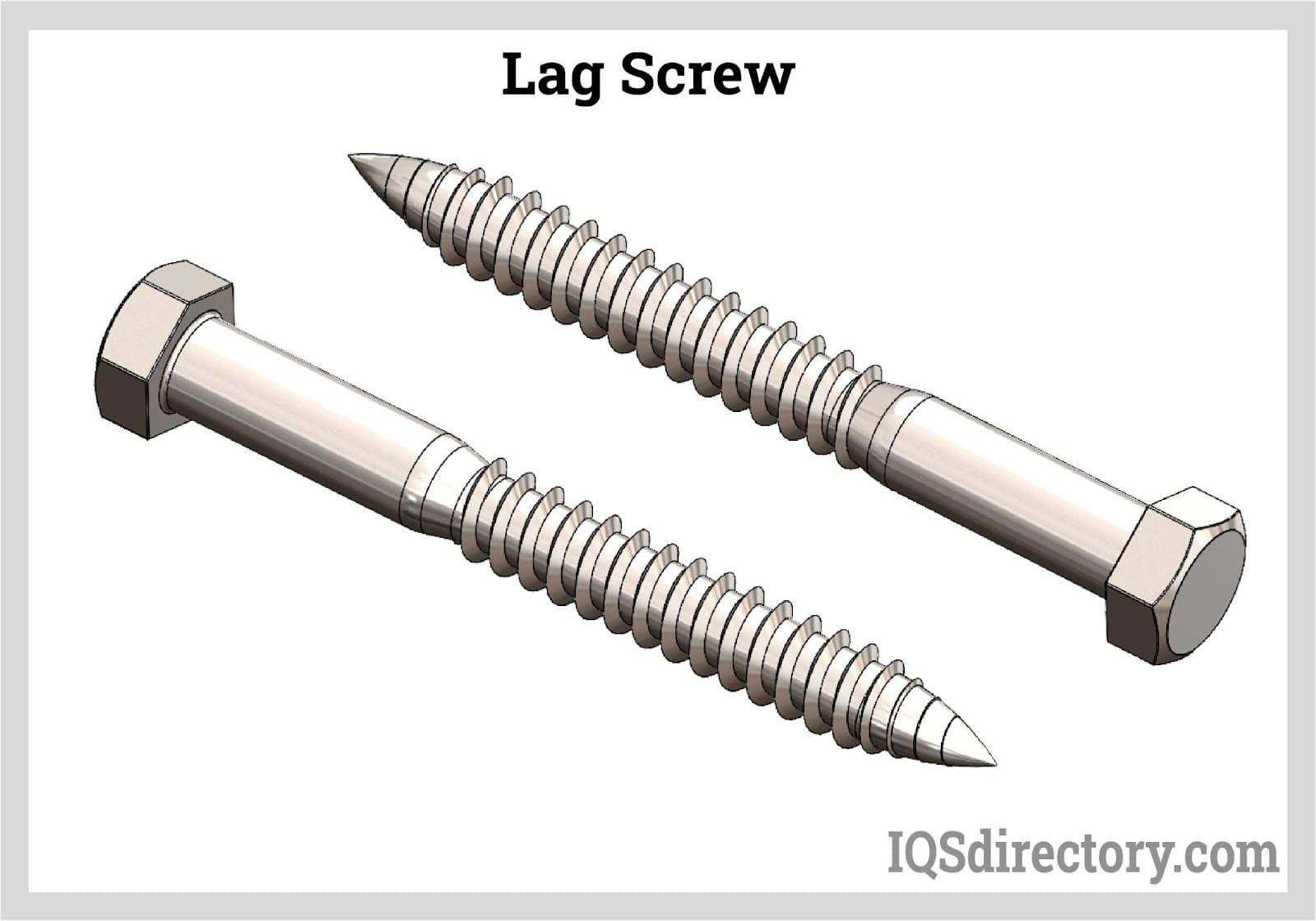

Lag Screws (Lag Bolts): Industrial-Strength Fasteners for Heavy-Duty Applications

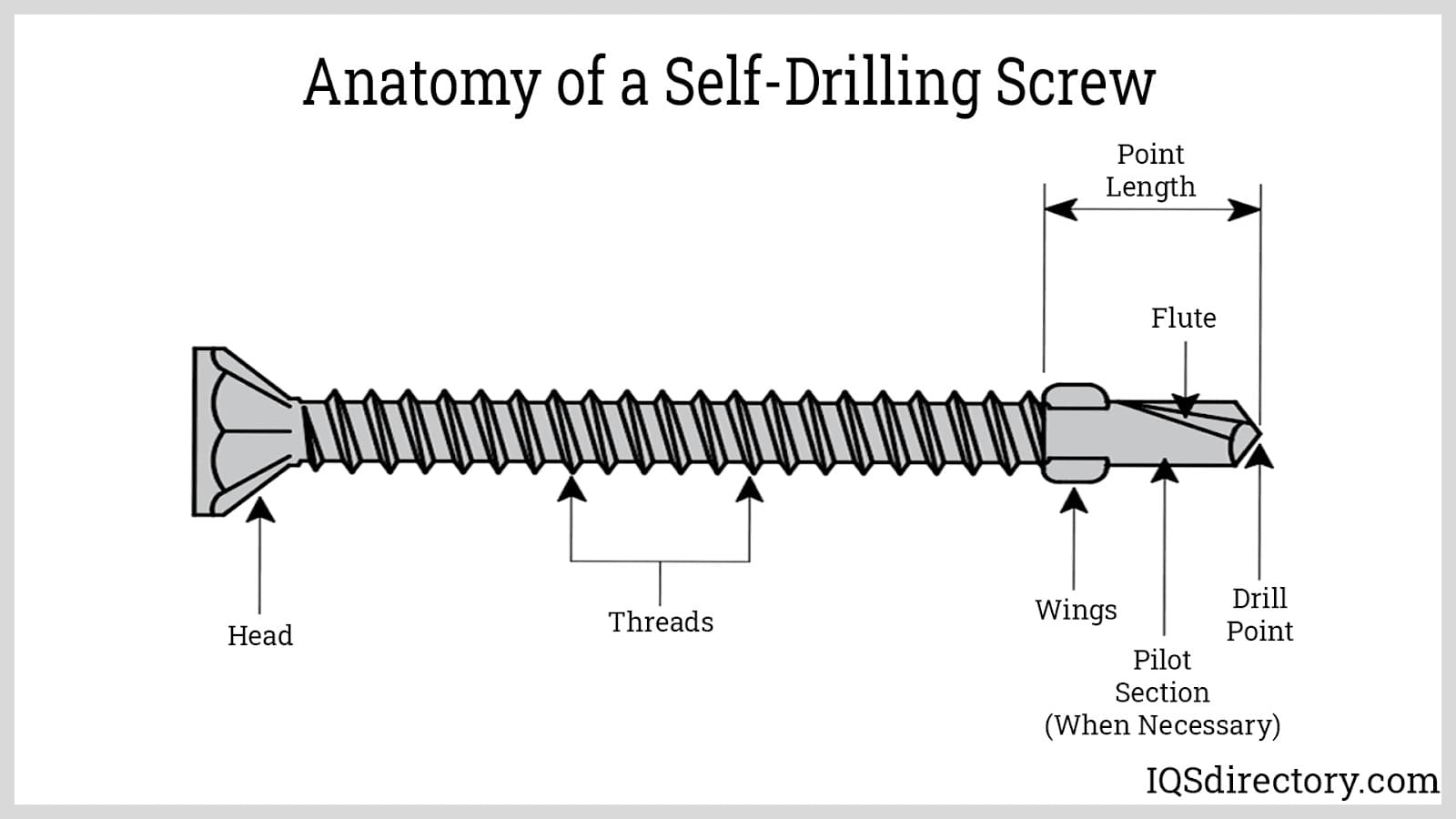

Lag screws, also known as lag bolts, are among the strongest fasteners available for construction and industrial applications. These heavy-duty screws are distinct from common sheet metal screws, self-drilling screws, and ordinary wood screws due to their substantial size, superior holding power, and ability to support high-stress joint connections. Lag screws are typically at least one inch long and one-quarter inch thick, with coarse threading that often does not run the full length of the shaft. To ensure optimal performance, a pilot hole must be drilled before installation. These fasteners are frequently paired with a nut to provide maximum strength, security, and to ensure that heavy structural materials remain securely fastened over time.

In the field of construction fasteners, lag screws are renowned for their exceptionally high load capacity and shear strength. They are the preferred choice for applications that demand reliability under heavy loads, such as timber frame construction, deck building, and large-scale structural assemblies. Unlike typical screws, lag bolts are engineered to withstand significant stress, making them ideal for connecting heavy lumber, supporting load-bearing beams, and anchoring structural supports to concrete or masonry. Their robust design makes them a staple in commercial, residential, and industrial construction projects where safety and long-term durability are critical.

Common uses for lag screws include securing wood-to-wood connections in decks, fences, and wooden playsets, anchoring metal hardware to wooden posts, attaching heavy-duty brackets, and fastening ledger boards for deck framing. They are also used in specialty applications such as mounting flat-screen TVs, securing heavy equipment, and anchoring support beams to concrete or stone surfaces. With their ability to bridge a wide range of materials—including wood, metal, masonry, and concrete—lag bolts are a versatile solution for the most demanding fastening requirements.

How Lag Bolts are Installed

Proper installation of lag screws is essential to maximize their holding capacity and prevent fastener failure. Are you wondering how to install lag bolts for maximum strength and safety? Follow these important steps for a secure and professional result:

- Align Materials: Begin by ensuring that all structural components are precisely aligned. Use clamps to securely hold the materials in place, preventing movement during drilling and installation.

- Drill a Pilot Hole: Using a drill bit that is slightly smaller than the diameter of the lag screw, create a pilot hole at the desired location. Drilling a pilot hole reduces the risk of splitting wood, improves screw penetration, and ensures a tight fit for the lag bolt threads.

- Position the Lag Screw: Insert the lag screw into the pilot hole. If additional strength is required, a washer and nut can be added on the opposite side of the material for extra security.

- Tighten the Lag Screw: Use a socket wrench or impact driver to tighten the lag screw. For best results, apply gradual and even pressure—over-tightening can strip threads or cause the fastener to snap inside the material.

- Consider Countersinking: Lag screws often feature large hex heads that may protrude from the surface, which can be unsightly or hazardous in areas with high foot traffic. To address this, use a spade bit to drill a countersink hole in the pilot hole so the screw head sits flush or below the surface.

Tip: Power tools can speed up installation, but always proceed cautiously to avoid overtightening or damaging the material. If a lag screw breaks off inside the substrate, removal and repair can be difficult and time-consuming.

Types of Lag Bolts: Materials and Finishes

Choosing the correct type of lag bolt is essential for optimal performance and longevity. Are you searching for the right lag screw for your specific application? Consider these primary types based on material and finish:

- Zinc-Plated Lag Screws: These are commonly used in interior applications where moisture and corrosion are minimal. The zinc coating provides basic corrosion resistance, making them ideal for indoor construction, cabinetry, and furniture assembly. However, zinc lag bolts are less prevalent and can be harder to source than other types.

- Hot-Dipped Galvanized Lag Bolts: The most popular and cost-effective choice, hot-dipped galvanized lag screws feature a thick zinc coating that offers superior corrosion resistance. They are especially suited for exterior projects, including decks, fences, and pressure-treated wood, where exposure to moisture and the elements is a concern. Galvanized lag bolts are also a top pick for marine environments and other demanding outdoor applications.

- Stainless Steel Lag Screws: When maximum corrosion resistance is required, stainless steel lag bolts are the premier option. Suitable for use in coastal regions, docks, piers, and areas with high salt exposure, these fasteners outperform galvanized types in resisting rust and degradation. While more expensive—often costing twice as much as galvanized lag bolts—stainless steel provides unmatched durability for critical infrastructure and marine construction.

Are you unsure which lag bolt material is best for your project? Consider the environment, load requirements, and long-term durability when choosing between zinc-plated, galvanized, and stainless steel fasteners.

Lag Bolts vs. Other Fasteners: What Sets Lag Screws Apart?

How do lag screws compare to other popular fasteners such as carriage bolts, wood screws, and structural screws? Lag screws are engineered for applications requiring superior holding power and long-term reliability. While wood screws are suitable for lighter-duty tasks, lag bolts are designed for heavy structural connections where failure is not an option. Carriage bolts, on the other hand, require access to both sides of the material for installation, whereas lag screws can be driven directly into a substrate with only one side accessible.

Additionally, lag bolts feature a hexagonal head that enables high torque application with standard wrenches or power tools, allowing for tighter and more secure fastening compared to slotted or Phillips head screws. Their thread design facilitates strong engagement with wood fibers while minimizing the risk of splitting or stripping, even under substantial load.

Key Applications: Where Are Lag Screws Used?

Lag screws are indispensable in a wide array of construction and industrial applications. Are you exploring the best fasteners for your next building project? Consider these common use cases where lag bolts deliver exceptional performance:

- Deck Framing and Construction: Lag bolts are a standard choice for attaching ledger boards to building frames, securing joists, and connecting heavy timber components in deck building projects.

- Outdoor Structures: Use lag screws to assemble pergolas, gazebos, playground equipment, and wood retaining walls, where long-term weather resistance and structural integrity are required.

- Structural Reinforcement: In residential and commercial construction, lag bolts are used to anchor beams, secure floor joists, and reinforce critical load-bearing connections.

- Mounting Heavy Equipment: From wall-mounted televisions to industrial machinery, lag screws provide the holding power needed to safely support heavy or dynamic loads.

- Wood-to-Concrete Connections: With the proper anchors, lag bolts are ideal for attaching wood structures to concrete foundations or masonry walls.

- Marine and Coastal Construction: Stainless steel lag bolts are essential for docks, piers, and any environment exposed to saltwater or high humidity.

- Fencing and Gate Installation: Secure fence posts, gates, and large outdoor fixtures where ordinary screws would fail under stress and exposure.

Advantages of Lag Bolts

What are the benefits of using lag bolts in construction and industrial projects? Here are the top reasons why professionals choose lag screws for demanding applications:

- Exceptional Strength and Load Capacity: Lag screws can withstand high pressure and heavy loads without cracking, breaking, or loosening, making them a staple in manufacturing, construction, and infrastructure projects.

- Superior Performance in Structural Applications: Their increased length and thickness provide greater holding power and enhanced resistance to shear and pull-out forces, ensuring components remain securely fastened even under dynamic or fluctuating loads.

- Long-Lasting Durability: Manufactured from high-carbon steel and protected with galvanized or stainless steel coatings, lag bolts resist rust and corrosion for decades—even in challenging environments with high moisture or salt exposure.

- Versatility Across Materials: Lag screws can be used to connect wood, metal, masonry, and even stone, offering flexibility for a wide range of construction and industrial fastening needs.

- Ease of Installation: With the right tools and pilot holes, lag screws can be quickly and securely installed by professionals or DIY enthusiasts alike, with minimal risk of installation errors.

- Cost-Effective Solution: For many applications, galvanized lag bolts provide an optimal balance of performance and affordability, reducing maintenance costs and prolonging the life of the structure.

Considerations When Choosing Lag Bolts

Before selecting lag screws for your project, consider these important factors to ensure the best results:

- Material Compatibility: Match the lag bolt material to the base material and environmental conditions. For example, use stainless steel for marine or coastal environments, and galvanized for outdoor construction with treated lumber.

- Size and Length: Select the appropriate diameter and length based on the thickness of the materials being fastened and the required load-bearing capacity.

- Thread Type: Coarse threads are ideal for wood, while finer threads may be necessary for certain metal applications.

- Head Style: Most lag bolts feature a hex head for easy torque application, but other head styles are available for specialized applications.

- Corrosion Resistance: Choose zinc-plated, galvanized, or stainless steel finishes based on exposure to moisture, chemicals, or salt.

- Compliance and Certification: For critical building projects, ensure that lag bolts meet relevant industry standards (such as ASTM, ISO, or DIN specifications) for quality and safety.

Frequently Asked Questions About Lag Screws

What size pilot hole should I drill for lag screws?

The pilot hole diameter should be approximately 70% of the screw's shank diameter for wood applications. For example, use a 3/16" pilot hole for a 1/4" lag screw.

Can lag bolts be used in concrete?

Yes, but a proper masonry anchor or shield must be used. Pre-drill the concrete with a masonry bit, insert the anchor, and then drive in the lag screw.

What are the most common sizes of lag bolts?

Lag screws are typically available in diameters from 1/4" to 1/2" and lengths from 1" up to 12" or more, with custom options available for specialized needs.

Do I need washers with lag screws?

Washers are recommended to distribute the load and prevent the screw head from embedding into the material, especially in softer woods or when high torque is applied.

Choosing the Right Lag Bolts Supplier

Are you ready to purchase high-quality lag bolts for your next project? Selecting a reliable lag bolts supplier is crucial for ensuring product quality, timely delivery, and expert technical support. To achieve the best outcome when buying lag bolts, we recommend comparing at least five companies using our comprehensive list of lag bolts manufacturers. Each supplier features a detailed business profile outlining their areas of expertise, manufacturing capabilities, and customer service standards.

When evaluating lag bolt suppliers, consider the following criteria:

- Product Range: Do they offer the sizes, materials, and finishes required for your application?

- Quality Assurance: Are their products tested and certified to meet industry standards?

- Customization: Can they manufacture custom lag bolts for unique requirements?

- Pricing and Lead Times: Are prices competitive, and do they offer prompt delivery to meet your project deadlines?

- Technical Support: Does the supplier provide guidance on fastener selection, installation, and application engineering?

- Customer Reviews: What do previous clients say about their experience with the supplier?

Use our proprietary website previewer to assess each supplier’s online presence and expertise. Once you’ve identified suitable suppliers, leverage our simple RFQ (Request for Quote) form to contact multiple lag bolt companies simultaneously. This streamlined process saves time and helps you secure the best value and quality for your project.

Related Fastener Solutions and Resources

Looking for more information on construction fasteners or related specialty hardware? Explore our comprehensive guides and supplier directories on:

If you have additional questions about lag screws, installation techniques, or fastener selection for your next construction or manufacturing project, contact our fastener experts for personalized guidance.

Conclusion: Why Choose Lag Screws for Heavy-Duty Fastening?

Lag screws (lag bolts) remain a foundational choice for builders, contractors, engineers, and homeowners seeking unmatched strength, reliability, and performance in fastening solutions. Their ability to secure heavy structural components, resist environmental stresses, and maintain long-term integrity makes them indispensable in modern construction and industrial applications. Whether you’re building a deck, anchoring a support beam, or assembling outdoor infrastructure, choosing the right lag bolt and supplier will ensure the success and safety of your project for years to come.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services