With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Blue Ribbon Fastener, we specialize in providing high-quality bolts and fastening solutions tailored to meet the demands of various industries. With a commitment to precision, reliability, and durability, we ensure that our products exceed performance expectations in even the most challenging applications. Our extensive selection includes a wide range of bolts, each manufactured to exact...

Delta Fastener Corp. supplies headed fasteners from only quality manufacturers. Our huge, readily available selection includes industrial bolts, nuts, washers, screws, etc. in a wide range of metal types and grades. Check out our online catalog or give us a call today for industrial bolts and more!

P&R is a manufacturer of industrial fasteners, specialty fasteners, automotive fasteners, stainless steel fasteners, aerospace and electronic fasteners. We provide over 60 years of experience in designing quality industrial fastener products. Give us a call so we can work together.

Chicago Nut & Bolt specializes in nonstandard products such as industrial bolts, stainless steel bolts, carriage bolts, titanium bolts, mil spec bolts and alloy bolts in any quantity. We will supply any shape or size depending on your requirements. We assure quality products and on-time delivery.

More U Bolt Manufacturers

U-bolts are essential fasteners in industrial and construction settings, characterized by their distinctive U-shape with threaded ends. These versatile bolts are engineered to support, anchor, and secure pipes, tubes, and round objects across a wide range of industries, including oil and gas, plumbing, construction, automotive, marine, and mechanical engineering. U-bolts’ curved design enables them to fit snugly around pipes, allowing for secure attachment to secondary structures or supports using nuts. Their primary roles include serving as pipe supports, guides, anchors, and fastening mechanisms, and, with certain installation methods, they can function as line stops to facilitate temporary pipe shutdowns. U-bolts are available in a wide array of sizes, materials, and finishes to meet diverse application requirements and industry standards.

Materials of U-Bolts

The choice of material for U-bolts is a critical decision, as it directly impacts the bolt’s durability, load-bearing capacity, corrosion resistance, and suitability for specific environments. The most commonly used materials for manufacturing U-bolts include:

- Plain Carbon Steel – Favored for its high tensile strength and cost-effectiveness, carbon steel U-bolts are commonly used in construction, automotive, and general industrial applications where environmental corrosion is minimal.

- Stainless Steel – Renowned for its superior corrosion resistance, especially grades like 304 and 316 stainless steel, these U-bolts are ideal for marine, chemical processing, and outdoor applications where exposure to moisture, chemicals, or saltwater is prevalent.

- Alloy Steel – Used for high-stress or high-temperature environments, alloy steel U-bolts offer enhanced mechanical properties and are often specified for power generation or heavy machinery installations.

To enhance corrosion resistance and extend the service life of U-bolts, manufacturers frequently apply specialized protective coatings. Common U-bolt coatings include:

- Zinc Plating – Provides a thin, cost-effective layer of corrosion protection, ideal for indoor or mildly corrosive environments.

- Hot-Dip Galvanization – Offers a thicker, more robust zinc coating, making U-bolts suitable for outdoor, coastal, or industrial settings where rust prevention is paramount.

- Thermoplastic Coating – Adds a durable and chemical-resistant outer layer, often used in water treatment, food processing, or environments where hygiene and chemical stability are priorities.

- Fluoropolymer Coating – Delivers exceptional chemical and temperature resistance, suitable for highly corrosive or reactive environments, such as chemical plants and refineries.

Looking for the right U-bolt material? Consider the specific environmental conditions, load requirements, and compliance standards your project demands. Explore common U-bolt applications to determine the optimal material and coating for your use case.

U-Bolts: Guides or Anchors?

U-bolts are exceptionally versatile and can be configured to serve as either guides or anchors for pipes and tubes. The installation method and tightness of the bolt determine whether the U-bolt allows movement (guide) or restricts it (anchor). This distinction is fundamental in applications such as pipe support systems, where controlling thermal expansion, vibration, and pipe movement is critical.

U-bolts are generally divided into two categories based on their function:

- Gripped U-bolts (Anchors) – Designed to tightly hold the pipe, preventing axial or lateral movement.

- Non-gripped U-bolts (Guides) – Allow for controlled movement, guiding pipes as they expand or contract with temperature changes or system operation.

Want to know which U-bolt is right for your piping system? Compare the different types of U-bolts and their applications to make an informed choice.

Non-Gripped U-Bolts: U-Bolts as Guides

A non-gripped U-bolt is the most common and straightforward method to serve as a pipe guide. In this setup, one nut is positioned on top of the support beam and another on the bottom. The nuts are then secured, intentionally leaving a small gap between the U-bolt and the pipe’s outer surface. This clearance allows the pipe to move axially (lengthwise) without restraint, accommodating thermal expansion, contraction, and system vibrations.

- Used to guide pipes along their axis in long pipe runs

- Helps prevent buckling and damage due to unrestricted expansion

- Common in HVAC, water distribution, and industrial piping systems

How do you prevent pipe stress due to thermal expansion? Using non-gripped U-bolts as guides ensures pipes can expand and contract safely, reducing maintenance costs and downtime.

Gripped U-Bolts: U-Bolts as Anchors

Gripped U-bolts serve as anchors by tightly clamping the pipe, eliminating any clearance between the U-bolt and the pipe's outer surface. This secure fit restricts both axial and lateral pipe movement at the support location, relying on the frictional force between the clamp and pipe surface.

While gripped U-bolts are effective as directional anchors for smaller pipes, it is important to recognize their limitations. The frictional grip may not be sufficient to withstand high axial forces or sudden line stops, potentially leading to slippage. For large-diameter pipes or high-stress applications, specialized pipe clamps or custom anchoring solutions may be required.

- Best for securing small-bore pipes in low to moderate load applications

- Often used as pipe anchors in HVAC, fire protection, and light industrial systems

- Not recommended for large or heavily loaded pipes where additional restraint is needed

Need to anchor pipes safely? Consult with a pipe support engineer or trusted U-bolt manufacturer to ensure the right bolt type and installation for your project.

Types of U-Bolts

U-bolts are available in several configurations to accommodate different mounting requirements, pipe shapes, and industry standards. Understanding the various types can help you select the ideal U-bolt for your application:

- Round U-bolts – Featuring a smooth, curved bend, these are the most common type and are specifically designed to fit around round pipes, tubes, and rods. They provide uniform clamping force and are suitable for most piping and conduit installations.

- Square U-bolts (Square-bend U-bolts) – With a 90° bend at each corner, square U-bolts are engineered to secure square or rectangular tubing, beams, or flat surfaces. They are often used in structural steel, channel framing, and racking systems.

- Bandage (Middle-bandage) U-bolts – These U-bolts incorporate a protective strip or “bandage” in the center, reducing friction and wear between the bolt and the object being fastened. This feature is particularly beneficial for sensitive or coated pipes, as it prevents damage during operation or vibration.

- Custom or Specialty U-bolts – Manufacturers can fabricate U-bolts to unique specifications, including extra-long legs, non-standard bends, or specialized coatings for unique industrial needs.

Curious about which U-bolt suits your structure? Learn how to measure U-bolt sizes and select the right type for your framework or pipework.

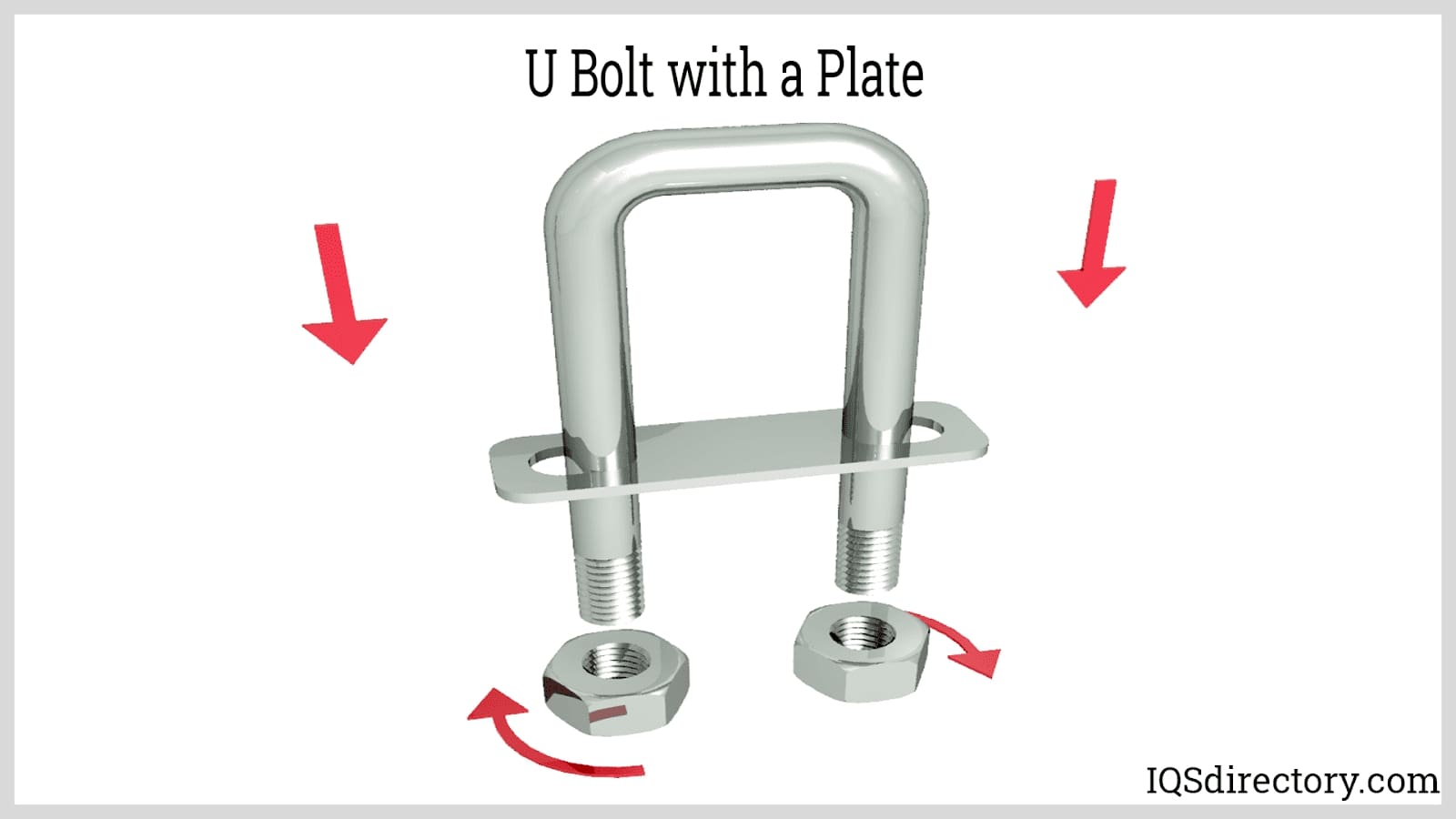

Installation of U-Bolts

Proper installation is crucial for maximizing the performance and longevity of U-bolts in any mechanical or structural system. Follow these step-by-step guidelines to ensure a secure and stable connection:

- Measure the pipe’s outer diameter (OD) to select a U-bolt with the appropriate size and shape (round or square bend).

- Choose nuts that match the U-bolt’s thread size and material for compatibility and strength.

- Drill holes in the support beam or structure, spacing them to align precisely with the U-bolt legs.

- Insert the U-bolt around the pipe and through the support holes, ensuring even positioning and correct orientation.

- Thread the nuts onto the U-bolt legs and tighten them evenly to the recommended torque specification. For non-gripped installations, maintain a slight clearance; for gripped installations, tighten until snug.

- Inspect the installation for alignment, tightness, and potential interference with pipe insulation or movement.

Some advanced installations may require additional accessories, such as saddle supports, vibration-damping pads, or anti-corrosion sleeves, especially in critical or high-load environments.

Need installation tips for your specific industry? Contact a U-bolt supplier or manufacturer’s technical team for best practices tailored to your application.

How to Measure U-Bolt Sizes

Accurate sizing is essential for selecting U-bolts that deliver optimal fit and structural integrity. Regardless of the bend style, the key U-bolt measurements are:

- Diameter – The thickness of the U-bolt rod, which determines its load capacity and strength.

- Leg Spacing (Inside Width) – The distance between the inner sides of the two legs, which must accommodate the pipe’s outer diameter or the width of the object being secured.

- Leg Length – The total length of each leg, which should be sufficient to pass through the support structure and allow for nut installation and tightening.

- Bend Type – Specify whether the U-bolt is round, semi-round, or square to match the contour of your pipe or mounting surface.

To ensure compatibility, always verify the relevant standards (such as ASME, ASTM, or ISO) and consult the manufacturer’s sizing chart.

Not sure what size you need? Request a sizing guide or technical consultation from a reputable U-bolt supplier.

Applications of U-Bolts

U-bolts are indispensable components in countless industries, providing reliable support and fastening solutions for a wide range of applications. Common uses include:

- Piping and Pipeline Support – U-bolts are widely used to secure pipes to beams, walls, ceilings, or other support structures in water supply, oil and gas, chemical process, and HVAC systems. They help maintain alignment, reduce vibration, and prevent pipe displacement.

- Plumbing Installations – In residential, commercial, and industrial plumbing, U-bolts offer simple and effective lateral constraints for pipes, especially in small-bore systems and where quick installation is needed.

- Electrical Conduit and Cable Management – U-bolts fasten conduits, cable trays, and wire bundles to support frames, keeping electrical systems organized and secure.

- Automotive and Vehicle Assembly – In automotive, trucking, and heavy equipment industries, U-bolts are used for axle mounting, suspension systems, exhaust systems, and frame assembly due to their strength and reliability.

- Marine and Offshore Structures – Stainless steel U-bolts are essential for securing masts, rigging, and pipes on boats, ships, and offshore platforms, offering corrosion resistance in saltwater environments.

- Construction and Structural Engineering – U-bolts are employed to anchor beams, secure handrails, and attach building components, ensuring structural stability in commercial and infrastructure projects.

- Shipping and Transport – U-bolts prevent pipe movement, breakage, and vibration during transportation of heavy or sensitive equipment, reducing the risk of damage and ensuring safe delivery.

- Renewable Energy – Used for mounting solar panels, wind turbine components, and support frames, U-bolts provide sturdy and adjustable fastening options.

U-bolts can support tubes up to 30 inches in diameter, with rod sizes typically ranging from 1/4 inch to 1 inch or more. Their adaptability makes them the preferred choice for fast, effective pipe restraint, especially in environments where vibration damping, thermal movement, and quick maintenance access are important.

Wondering if U-bolts are suitable for your project? Connect with a U-bolt manufacturer to discuss application-specific requirements and get expert recommendations.

Benefits of Using U-Bolts

Selecting U-bolts for your fastening and support needs offers several clear advantages:

- Versatility – Suitable for pipes, tubes, conduits, and a variety of structural elements, across many industries.

- Ease of Installation – Simple design allows for rapid installation, adjustment, and removal, minimizing labor and downtime.

- Strong Load-Bearing Capacity – Engineered to withstand significant axial and lateral forces, ensuring stability even in demanding environments.

- Corrosion Resistance – Available in stainless steel and with specialized coatings, U-bolts offer long service life in harsh or corrosive settings.

- Cost-Effective – Readily available in standard sizes and materials, U-bolts provide a low-cost solution for secure fastening.

- Customizable – Can be manufactured to meet unique size, material, and coating requirements for specialized applications.

Interested in maximizing your system’s performance? Incorporate U-bolts to improve alignment, reduce vibration, and extend the lifespan of piping and structural systems.

Decision Factors for Choosing U-Bolts

When selecting U-bolts for a specific application, several key factors should be evaluated to ensure optimal performance and compliance:

- Pipe or Object Size – Ensure the U-bolt matches the diameter or width of the item being secured.

- Load Requirements – Consider the weight, vibration, and potential forces acting on the bolt during operation.

- Environment – Assess exposure to moisture, chemicals, temperature extremes, or corrosive elements to choose appropriate materials and coatings.

- Compliance Standards – Verify adherence to industry regulations (ASME, ASTM, ISO, etc.), especially for critical or safety-sensitive installations.

- Installation Constraints – Evaluate available space, accessibility, and compatibility with existing structures or supports.

- Cost and Availability – Balance quality, lead time, and budget considerations by comparing products from multiple suppliers.

Ready to select the right U-bolt? Review our list of trusted manufacturers and request technical data or a custom quote.

Choosing the Proper U-Bolts Manufacturer

Finding a reliable U-bolt manufacturer or supplier is crucial for project success, quality assurance, and compliance with industry standards. To ensure you select the best partner for your needs:

- Compare at least six reputable U-bolt companies using our curated list of U-bolts suppliers.

- Review each manufacturer’s business profile to assess their experience, product range, certifications, and industry specialties.

- Use our integrated website previewer to quickly explore their offerings and technical resources.

- Contact manufacturers directly via their profile’s inquiry form to request detailed information, technical support, or a competitive quote.

- Leverage our streamlined RFQ (Request for Quote) form to communicate with multiple U-bolt companies simultaneously, saving time and ensuring you receive the best pricing and delivery options.

Still have questions? Reach out to our technical advisors for personalized recommendations, product samples, or to discuss custom U-bolt fabrication for your application.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services