Bolt Products has been a leading supplier of a variety of fasteners, including industrial, mil spec, metric, stainless steel, plastic and high strength fasteners, since 1947. We offer a complete line of high-quality, industrial fastening products to customers around the world.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for bolts tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide...

Manufacturer of fasteners, custom hardware and precision machined components of industrial, aerospace, power generation, petrol-chemical, military, nuclear and commercial applications. Among our industrial bolt offerings are heavy hex bolts, finished hex bolts and oval neck track bolts.

More U Bolt Manufacturers

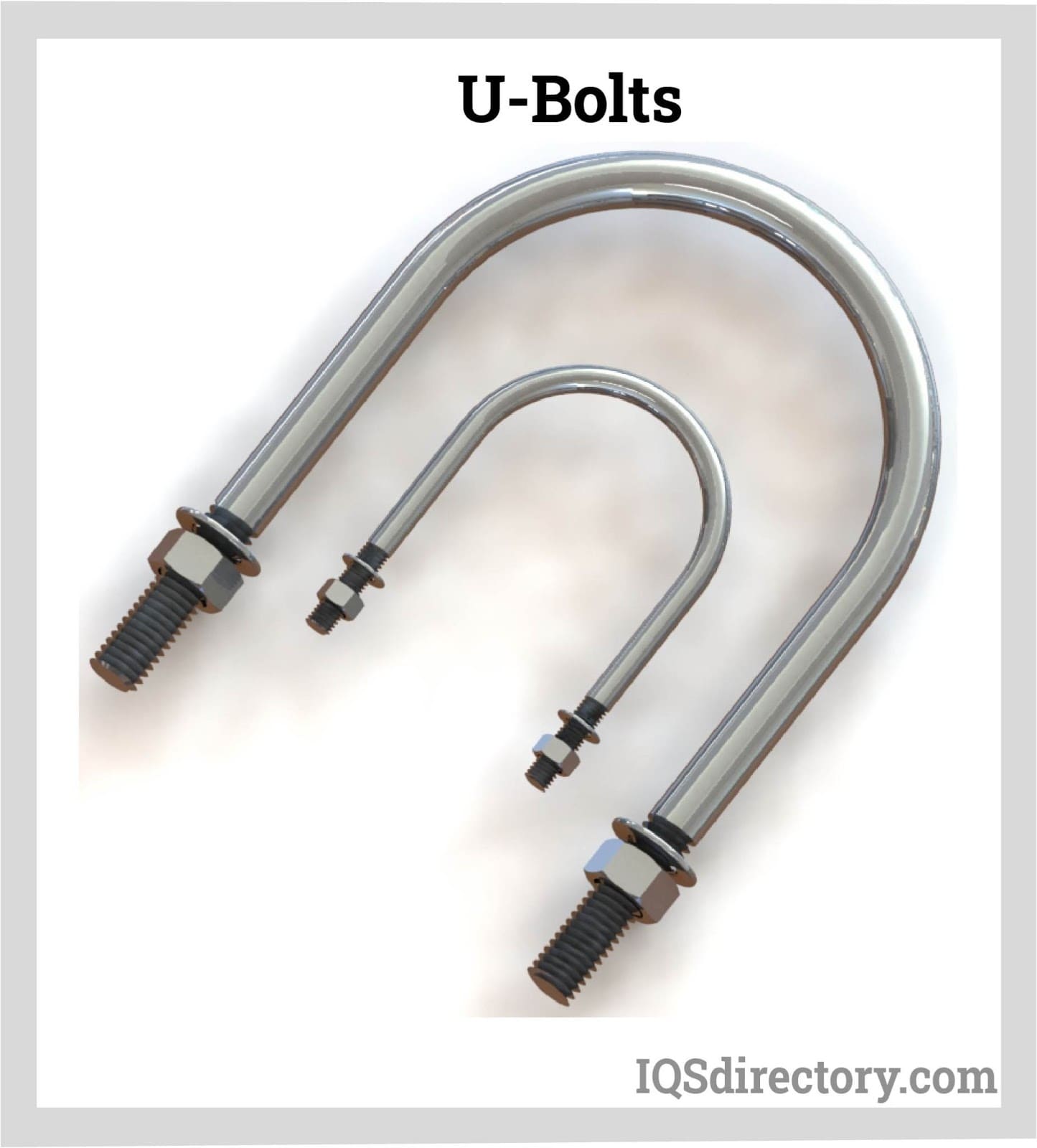

U-bolts are curved bolts with a U-shape and threads on each end that are used as supports in the pipe and pipeline sector. U-bolts' curved design lets them easily fit around pipes, which are subsequently fastened to a secondary element using nuts. They primarily serve as rest, guide, and fastening supports, but with certain installation modifications, they can also serve as line stops, used to create temporary pipe shut down options. They are easily accessible in a range of thicknesses and sizes.

Materials of U-Bolts

Although there are various strong and resilient materials used to create U-bolts, plain carbon steel and stainless steel are most commonly used. To stop corrosion, protective coatings may occasionally be added. Typical U-bolt coatings include:

- Zinc Plating

- Hot-Dip Galvanization

- Thermoplastic Coating

- Fluoropolymer Coating

U-Bolts: Guides or Anchors?

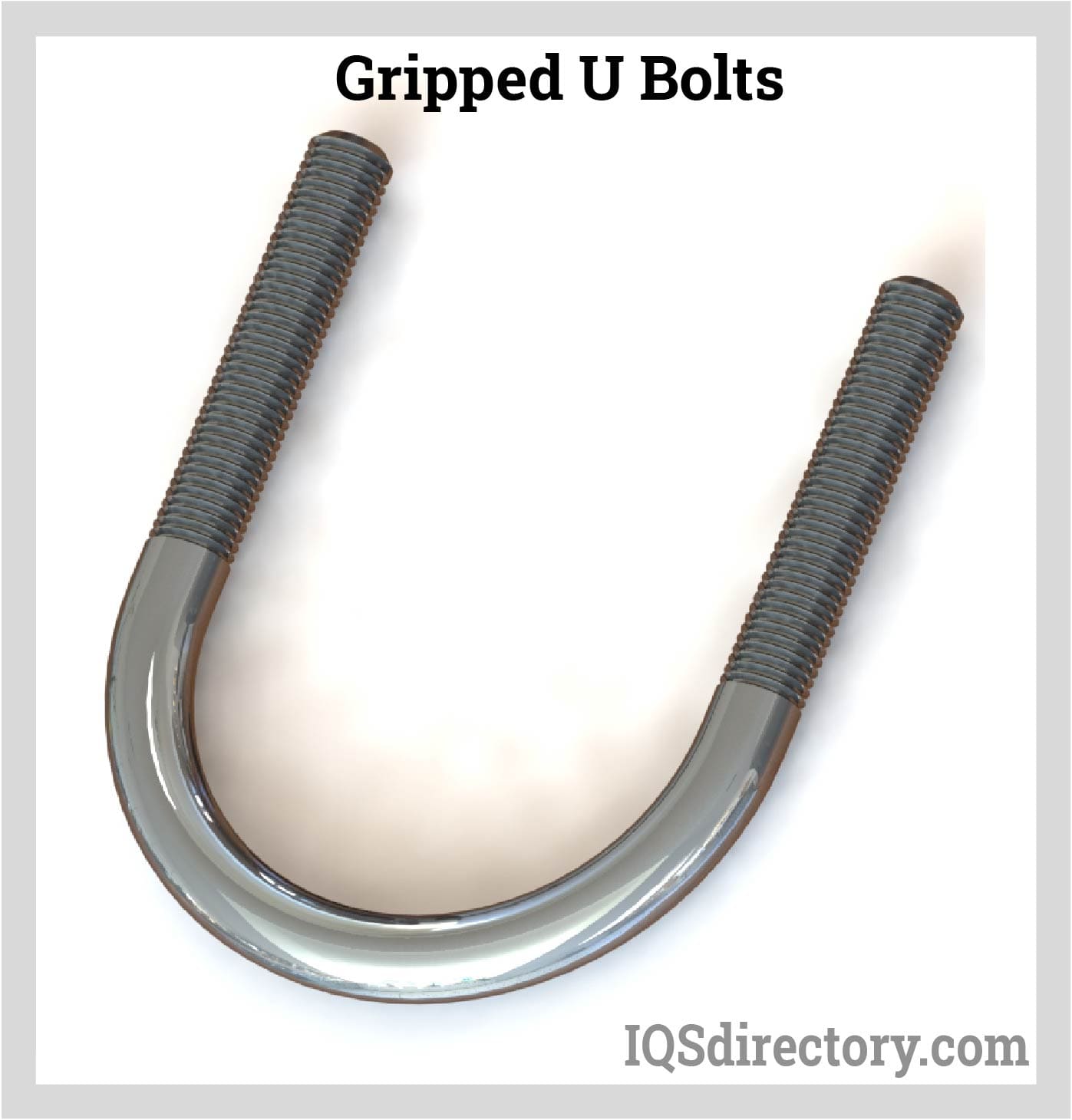

U-bolts are typically employed as guides and for securing pipes. They can also be utilized as anchors to prevent pipes from shifting. U-bolts are divided into two groups: gripped U-bolts and non-gripped U-bolts, depending on what function they perform.

Non-Gripped U-Bolts: U-Bolts as Guides

A non-gripped U-bolt is the most popular and straightforward installation to serve as a pipe guide. One nut is positioned on top of the support beam, and another is placed on the bottom when installing non-gripped pipe U-bolts. The two nuts are then secured, leaving a space between the U-bolt surface and the pipe. As a result, axial mobility is not impeded with a non-gripped U-bolt.

Gripped U-Bolts: U-Bolts as Anchors

Gripped U-bolts act as an anchor and prevent pipe movement at the support site. A U-bolt must be fitted so there is no space between the pipe and the U-bolt in order to properly function as an anchor. When functioning as an anchor, a U-bolt is positioned at the base of a secondary support structure and tightened until it is snug against a pipe.

Pipe movement in the axial direction is constrained by the friction force between the clamp and pipe surfaces, acting as a directional anchor. However, the frictional force may not be able to sustain the axial force and may slip when the line stops and axial forces increase. This potential slippage is why U-bolt anchors are only effective with smaller pipes.

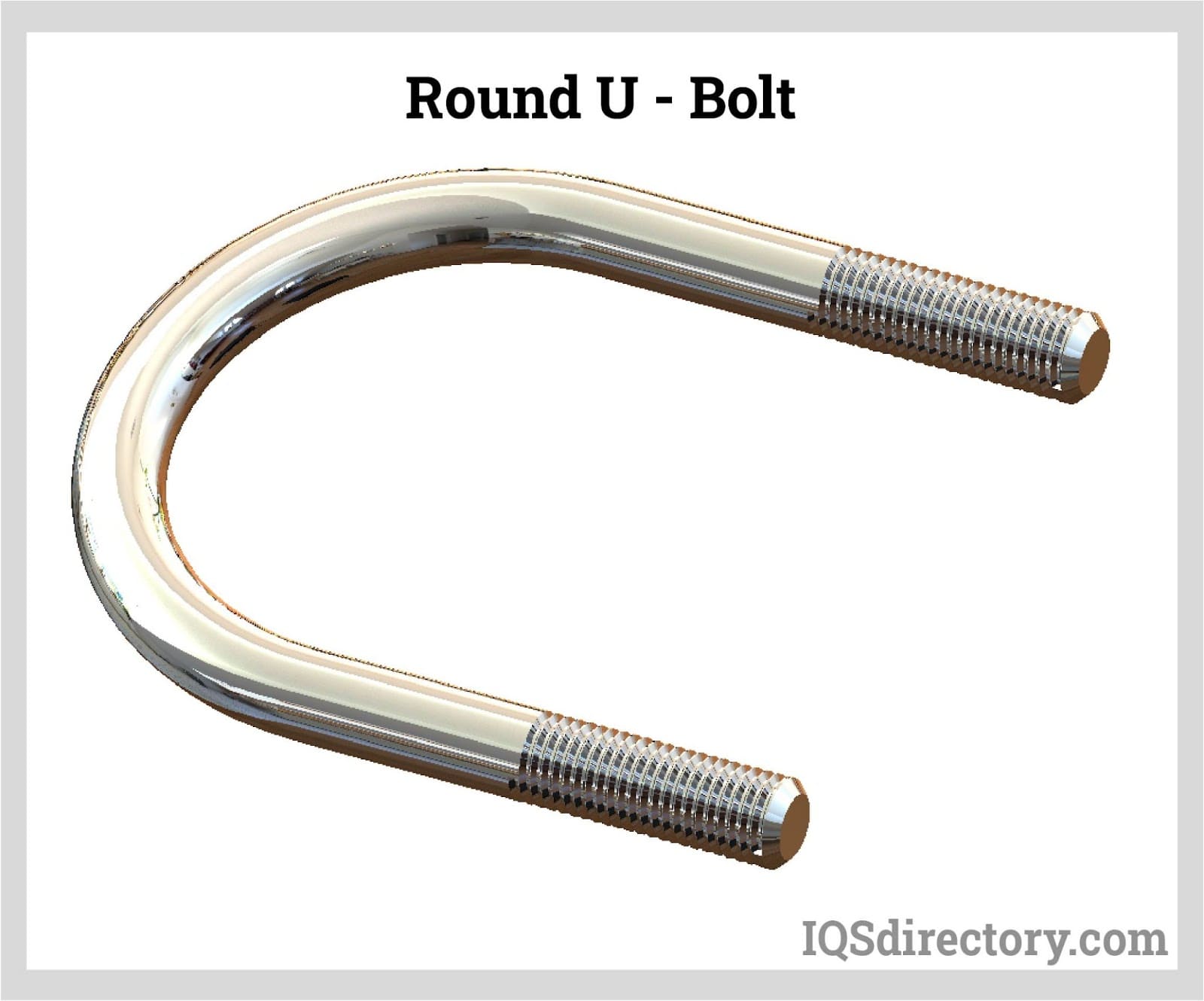

Types of U-Bolts

Although there are other U-bolts used to attach tension clamps and ball sockets on transmission lines, the two primary varieties of U-bolts used are classified as middle bandage U-bolts (those featuring a protective strip in their center to reduce friction between themselves and the devices they are installed to) or square U-bolts (also known as square-bend U-bolts, they feature a 90° at each bend). Depending on its design, a square U-bolt could also have a bandage. Both bandage U-bolts and square U-bolts are utilized to secure cross arms.

Rounded U-bolts: As the name suggests, round(ed) U-bolts feature round bends. They are typically used to secure pipes to round surfaces.

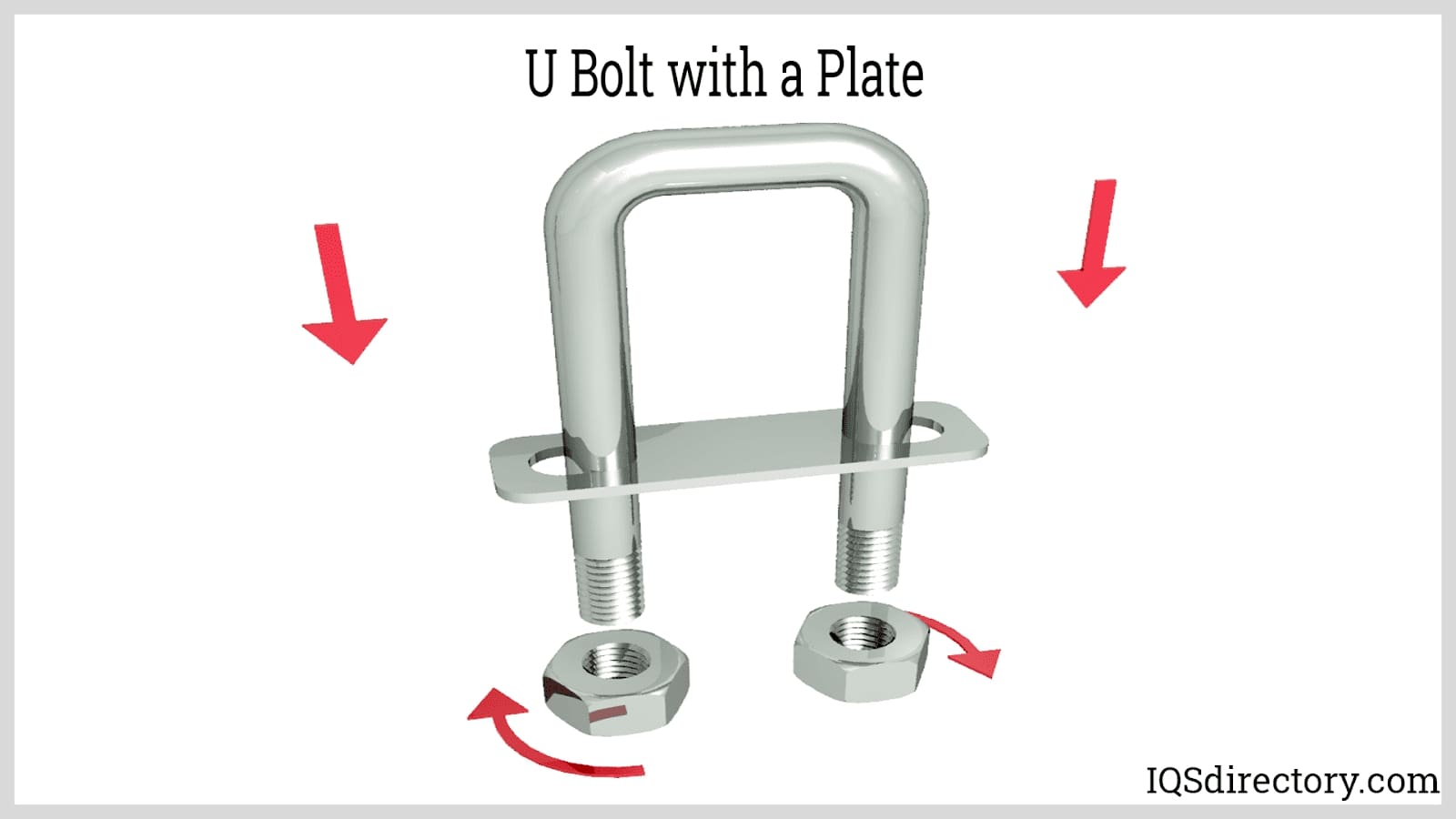

Installation of U-Bolts

A pipe U-bolt is relatively simple to install. First, the OD (outer diameter) of the pipe is used to determine the necessary U-bolt size. Once sized to make sure the pipe will fit inside the bolt, make sure the nuts match the threads. Then, depending on the type of support, the only task is to drill the hole in the support beam, precisely position the bolt through those holes, and tighten the nuts.

How to Measure U-Bolt Sizes

Regardless of the degree of bend featured in a U-bolt, U-bolts are measured in the same way. U-bolt size is specified as diameter x leg spacing x leg length. Measurements include the bend type, which might be square, circular, or semi-round.

Applications of U-Bolts

U-bolts are typically coupled with pipes of the same size. Although the sizes may differ, they are intended to fasten. U-bolts can support tubes up to 30 inches in diameter and have rod sizes ranging from 1/4 inch to 1 inch. U-bolts can be used in a variety of situations. For example, they are frequently employed as piping-support mechanisms.

In addition, U-bolts are frequently used in plumbing solutions to give pipes lateral constraints. U-bolts are the most direct and often utilized piping support for small-bore systems. U-bolts are frequently used in plants to support bare pipes smaller than 8 inches in diameter.

As was previously mentioned, U-bolts can act as a rest, a guide, or a securing mechanism. U-bolts can reduce line vibrations by providing a system with more rigidity. U-bolts are a useful option for supporting elevated vertical runs of pipe. U-bolts are used in the shipping sector to prevent the movement and breaking of pipes during delivery. U-bolts stop erratic pipe movements brought on by heavy weights, changes in direction, and other factors during transport.

Choosing the Proper U-Bolts Manufacturer

To make sure you have the most beneficial outcome when purchasing U-Bolts from a U-Bolts Manufacturer, it is important to compare at least 6 Companies using our list of U-Bolts suppliers. Each U-Bolts Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each U-Bolts company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple U-Bolts companies with the same message.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services