Bolt Products has been a leading supplier of a variety of fasteners, including industrial, mil spec, metric, stainless steel, plastic and high strength fasteners, since 1947. We offer a complete line of high-quality, industrial fastening products to customers around the world.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for bolts tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide...

Manufacturer of fasteners, custom hardware and precision machined components of industrial, aerospace, power generation, petrol-chemical, military, nuclear and commercial applications. Among our industrial bolt offerings are heavy hex bolts, finished hex bolts and oval neck track bolts.

More Anchor Bolt Manufacturers

Used widely in building construction, highway systems, electrical towers, power treatments and marine industries, anchor bolts are an essential method of securing large components to a solid foundation to ensure against structural failure or damage.

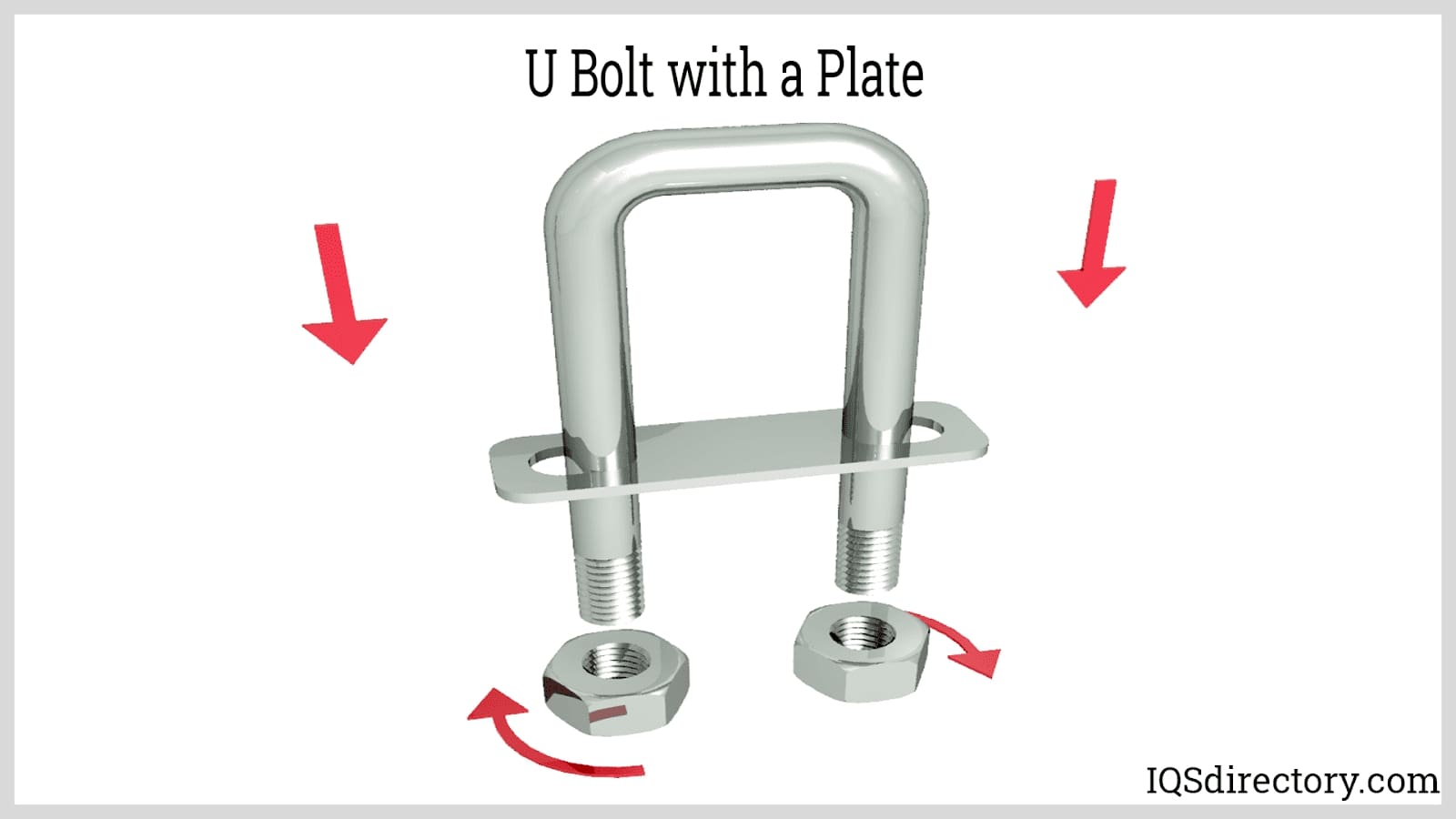

In applications such as bridges and tunnels, for the holding of large tanks and machines, and in many large buildings to connect the foundations to the walls for improved earthquake resistance, anchor bolts are able to provide a stable connection. Anchor bolts are also called cast-in place bolts. The heavy duty bolt is set into wet concrete headfirst and once the concrete has hardened, the threaded end of the bolt is attached to a component which anchors the bolt to its intended external load. Anchor bolts are commonly used because they provide a strong fastening with minimal room for error. Setting a bolt into wet concrete can be tricky, but once it has hardened, the bolt is very secure and able to hold a large amount of tension.

There are several different types of anchor bolts which will be chosen determined by the intended applications. Bent rods, hook bolts or J bolts, sleeve bolts and swaged bolts are some of the most common types of anchor bolts. Another widely used type is wedge anchors. These use a wedge shape bolt end, combined with a fastening sleeve to ensure a secure connection within the concrete setting. These need to be deeply embedded into the concrete so that the bolt cannot be pulled out under extreme force. For shallow installation, machine screw anchor bolts should be used. In terms of determining the most suitable type of bolt for an application, there are a number of factors to consider in terms of the demands placed on the bolts with corrosion, strength capacity and physical environment.

Steel and carbon are commonly used to construct bolts as they are durable materials with strong physical properties. Stainless steel bolts are resistant to corrosion and are able to maintain their shape and strength even in high temperatures and extreme environments. Industrial bolts are also commonly galvanized, as this further increases the strength of a material. In terms of construction, the diameter of a bolt will increase with the need for greater strength and resistance. Anchor bolts are able to be used with high demand and high stress applications as they can withstand the tension produced by the holding system.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services