Bolt Products has been a leading supplier of a variety of fasteners, including industrial, mil spec, metric, stainless steel, plastic and high strength fasteners, since 1947. We offer a complete line of high-quality, industrial fastening products to customers around the world.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for bolts tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide...

Manufacturer of fasteners, custom hardware and precision machined components of industrial, aerospace, power generation, petrol-chemical, military, nuclear and commercial applications. Among our industrial bolt offerings are heavy hex bolts, finished hex bolts and oval neck track bolts.

More Lag Bolt Manufacturers

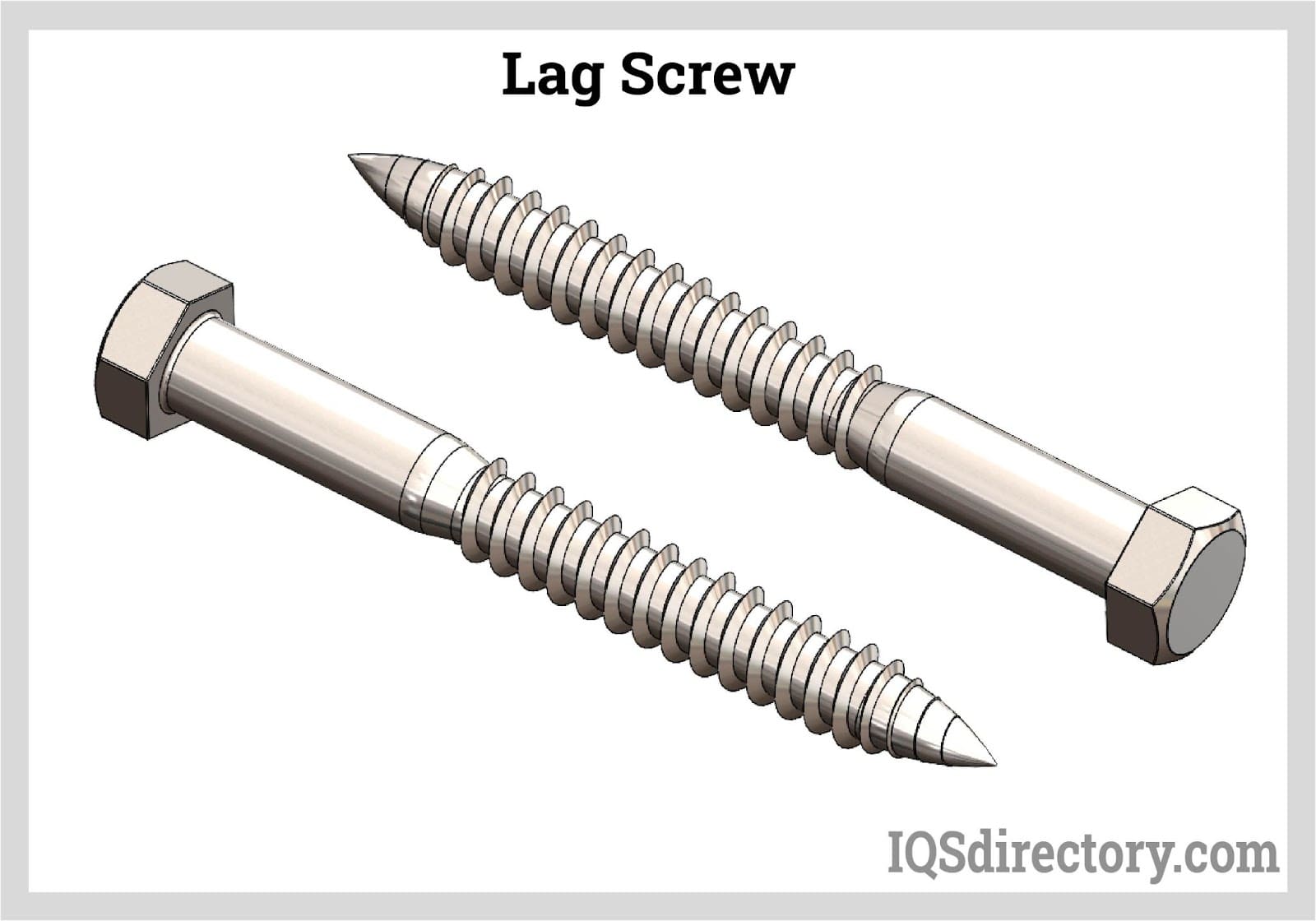

Lag screws, which are also sometimes referred to as lag bolts, are among the strongest fasteners. These screws are distinct from common sheet metal, self-drilling, and wood screws. Lag screws are enormous when compared to the majority of these more-common screws. Lag screws are at least one inch long and one-quarter inch thick. Although the threading on these screws may be coarse, it does not extend to their entire length. Lag screws need a hole to be drilled into an object before they can be used. A nut is also used with lag screws to increase their strength and security and to aid in holding items together.

Lag screws are typically used in applications with heavy loads since they have a substantially higher load capacity than the typical sheet metal or wood screw. Although lag screws are often used to secure wood components just like wood screws, lag screws can also be used to secure metal, concrete, and even stone fixtures. These incredibly-strong fasteners are used to connect heavy lumber or other materials bearing a significant weight, build things like decks, link lumber around the house, and maintain your flat-screen TV's long-term attachment to the wall.

How Lag Bolts are Installed

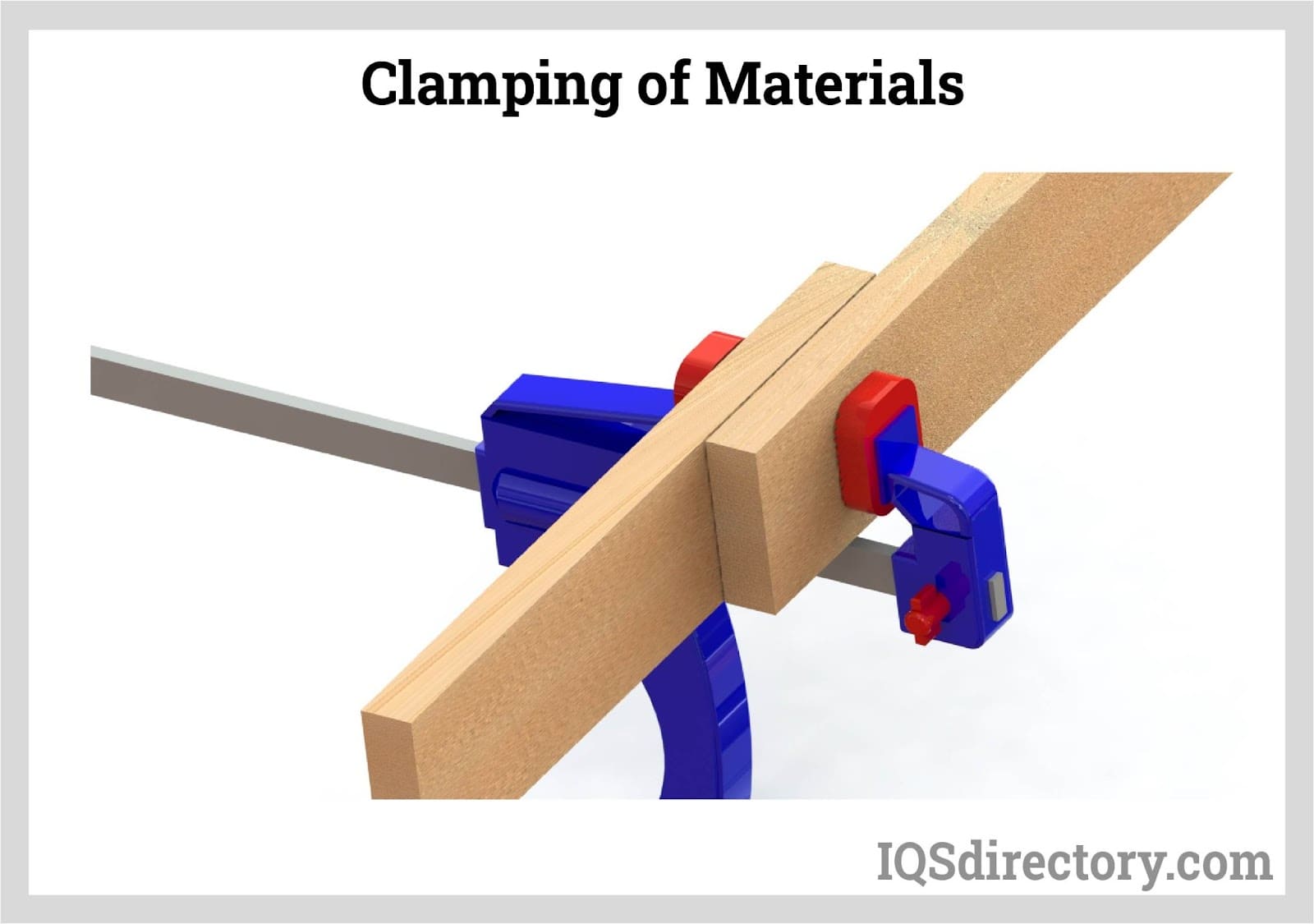

The first step in installing lag screws is to confirm that all of the materials utilized in an application are properly aligned. Then, clamps should be used to securely hold everything in place. Next, drill a pilot hole with a slightly smaller diameter than the lag screw that will be used to ensure everything is securely fastened. Finally, make sure to drill through the exact spot where the screw will eventually be placed to complete the hole.

Large hex heads on lag bolts tend to stick out from the material when they are fastened. Consider lag bolt heads that protrude on a level deck as an example of how this could be ugly or even dangerous in some circumstances. One can drill countersink holes as a workaround to conceal the bolt head within a material.

Using a big spade drill bit, create a countersink hole in the previously-drilled pilot holes. Make sure to measure the diameter of the lag bolt head and provide enough space for the socket wrench to fit and perform its function of securing the bolt with the material. One may use a motorized drill if a bit is available. If one wants to follow this route, move cautiously and slowly. If a user fastens a bolt too tightly, it may break off inside the material and create a severe headache.

Types of Lag Bolts

Typically, lag screws come in three finishes: zinc, hot-dipped galvanized, and stainless steel. Screws made of zinc are frequently utilized in interior applications. Unfortunately, zinc lag bolts are less common and more difficult to find than the other varieties.

Lag bolts that have been hot-dipped galvanized are the most popular and least expensive option. In addition, lag bolts that have been hot-dipped galvanized, often known as galvanized, are excellent for use with pressure-treated wood and outdoor applications because they are corrosion-resistant.

The most expensive lag screws are made of stainless steel. They may be up to twice as expensive as standard galvanized lag screws. Stainless steel bolts are utilized when beams are in contact with water or in situations with high levels of salt. The most typical applications for stainless steel lags are found with dock and oceanside buildings.

Advantages of Lag Bolts

- Lag screws can withstand high pressure without cracking or suffering any harm. As a result, lag screws are frequently used by manufacturing and construction firms to link large objects.

- Lag screws provide a greater level of performance since they are longer and thicker than other screws. They remain in place thanks to their strength and durability even when under the weight of heavy, massive objects.

- Lag screws are long-lasting in addition to having outstanding strength and endurance. A typical lag screw has a core made of high-carbon steel and an external shell of galvanized zinc. The galvanized zinc covering shields the screw's steel core from rust and corrosion. Lag screws don't typically rust or corrode because moisture and oxygen can't easily pass through galvanized zinc. As a result, they provide a great level of stability and security to the things on which they are employed while lasting for decades.

Choosing the Right Lag Bolts Supplier

To make sure you have the most constructive outcome when purchasing Lag Bolts from a Lag Bolts Supplier, it is important to compare at least 5 Companies using our list of Lag Bolts manufacturers. Each Lag Bolts Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Lag Bolts company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Lag Bolts businesses with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services