Our company has manufacturing experiences dating back to 1970 and over the years we have grown into an international supplier of bolts.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

As a distributor, Blue Ribbon Fastener offers a variety of industrial bolts including carriage bolts, elevator bolts, lag bolts, stripper bolts, plow bolts, hanger bolts, elevator bolts, stud bolts and toggle bolts. Custom and standard products are available in virtually any material.

Here at Eagle Fastener Corporation, we stand proudly as a trusted leader in the realm of bolts, offering a comprehensive array of products, services, and capabilities to cater to the diverse needs of our esteemed clientele. With an unwavering commitment to excellence and extensive expertise in bolt manufacturing, we are poised to deliver innovative solutions that excel in quality, reliability,...

Connect With Recommended Industrial Bolt Suppliers

Provide us with your project specifications, and we’ll connect you with our network of qualified plating & coating suppliers who can give you a free proposal. Our team has been manually sourcing and curating the best U.S. manufacturers for over 20 years.

Request for QuoteWe're the #1 destination for finding U.S. Manufacturers

More Stud Bolt Manufacturers

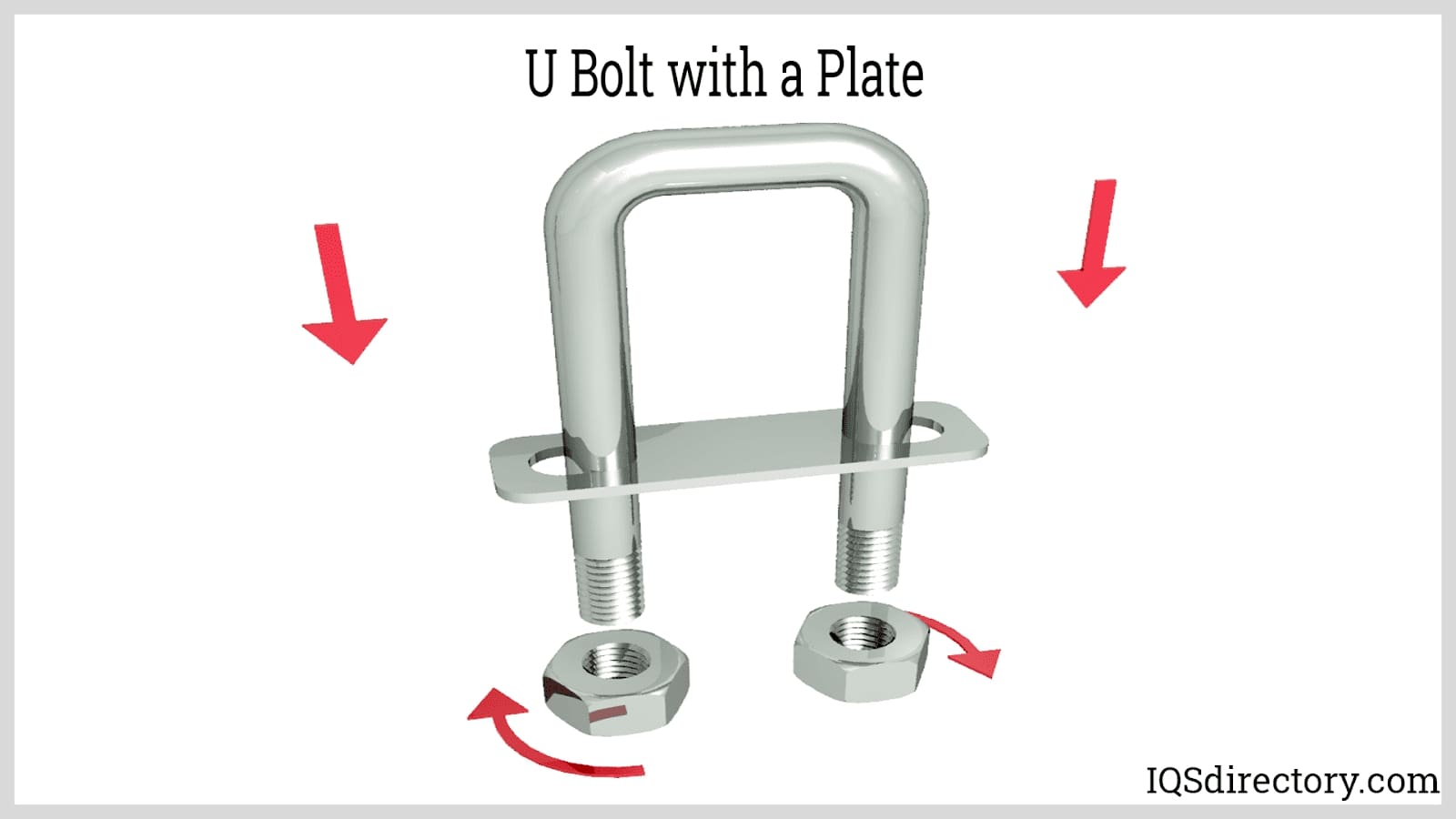

Unlike many types of bolts, this particular style is not driven into an object or surface, but passed completely through. Nuts or flanges on either end of the bolt then hold the two objects firmly together. The ability to adjust the tightness is a key element lending to the popularity of the stud bolt in a variety of applications.

Engineering, motor, automotive, petrochemical and nuclear industries all make use of these bolts which can be specially contoured to distribute stress evenly, reducing the occurrence of breakages. Internal combustion engine cylinders, inspection covers, tank lids, car wheels and even domestic gate latches use this simple but effective design. While the dual ended nature of the stud bolt is one of its greatest assets, it can also be use as an anchor bolt in civil and architectural engineering.

This is accomplished through cast-in-place techniques that insert one end of the rod into setting concrete. The threaded end provides added resistance to pullout and machinery or other objects may be fastened to the exposed threading with a single nut or flange. The materials used for stud bolts and corresponding nuts and flanges depend largely on the use, though steel alloys are the industry standard. Zinc and cadmium plating are common finishes that enhance the corrosion and environmental resistance of steel.

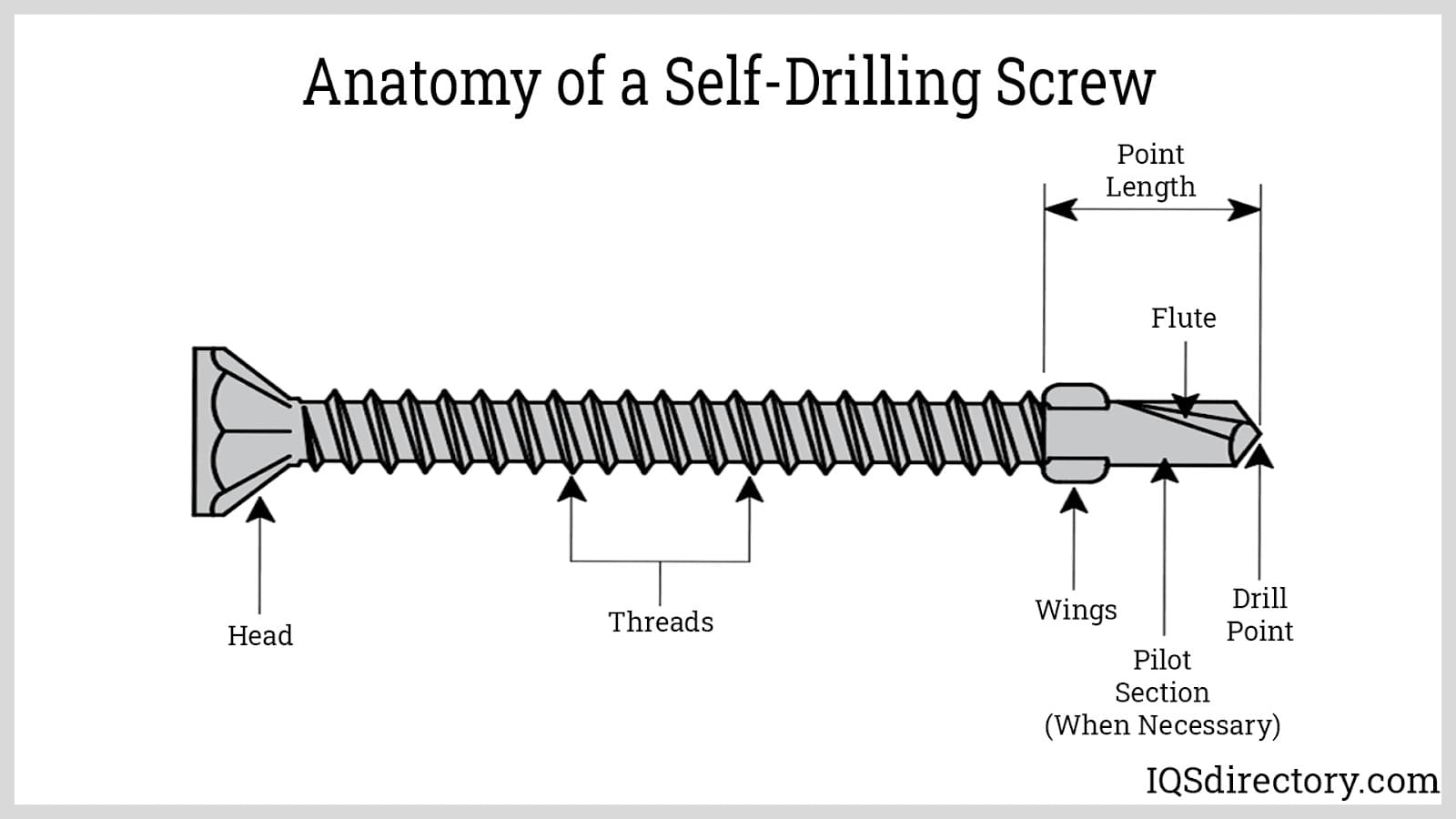

The manufacturing process used to create stud bolts is similar to that of other bolt types. A steel wire rod is first heated consistently for an extended period of time and all rust particles are removed. If needed, the metal is coated for added protection. Cold forging is then used to shape the rod at room temperature and the rod is forced through dyes at high pressures to be shaped into long perfectly round rods. Once cut down to the desired length, cold forging is again used to implement high pressure rollers which press in the thread pattern.

In stud bolts, threading is either pressed along the entire rod, or on equal portions of each end, leaving a smooth center segment. The finished bolt is then ready for use in a variety of applications. A pilot hole is made in each of the objects or surfaces to be joined and the rod is inserted. A nut or flange is then tightened on each end to create the desired clamping force. A wrench, spanner or pliers may be used when tightening must be high and precise. Stud bolts with a smooth center fragment should be considered carefully.If a tight fit is desired than this portion must have a width the same or smaller than the combined width of the articles to be fastened. Alternatively, a wider segment allows the surfaces to "float," providing a degree of give. It is important to consider the materials to be fastened as well as the strength and corrosion resistance required of the bolt materials. Other considerations include the bolt length and diameter.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services