Bolt Products has been a leading supplier of a variety of fasteners, including industrial, mil spec, metric, stainless steel, plastic and high strength fasteners, since 1947. We offer a complete line of high-quality, industrial fastening products to customers around the world.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for bolts tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide...

Manufacturer of fasteners, custom hardware and precision machined components of industrial, aerospace, power generation, petrol-chemical, military, nuclear and commercial applications. Among our industrial bolt offerings are heavy hex bolts, finished hex bolts and oval neck track bolts.

More J Bolt Manufacturers

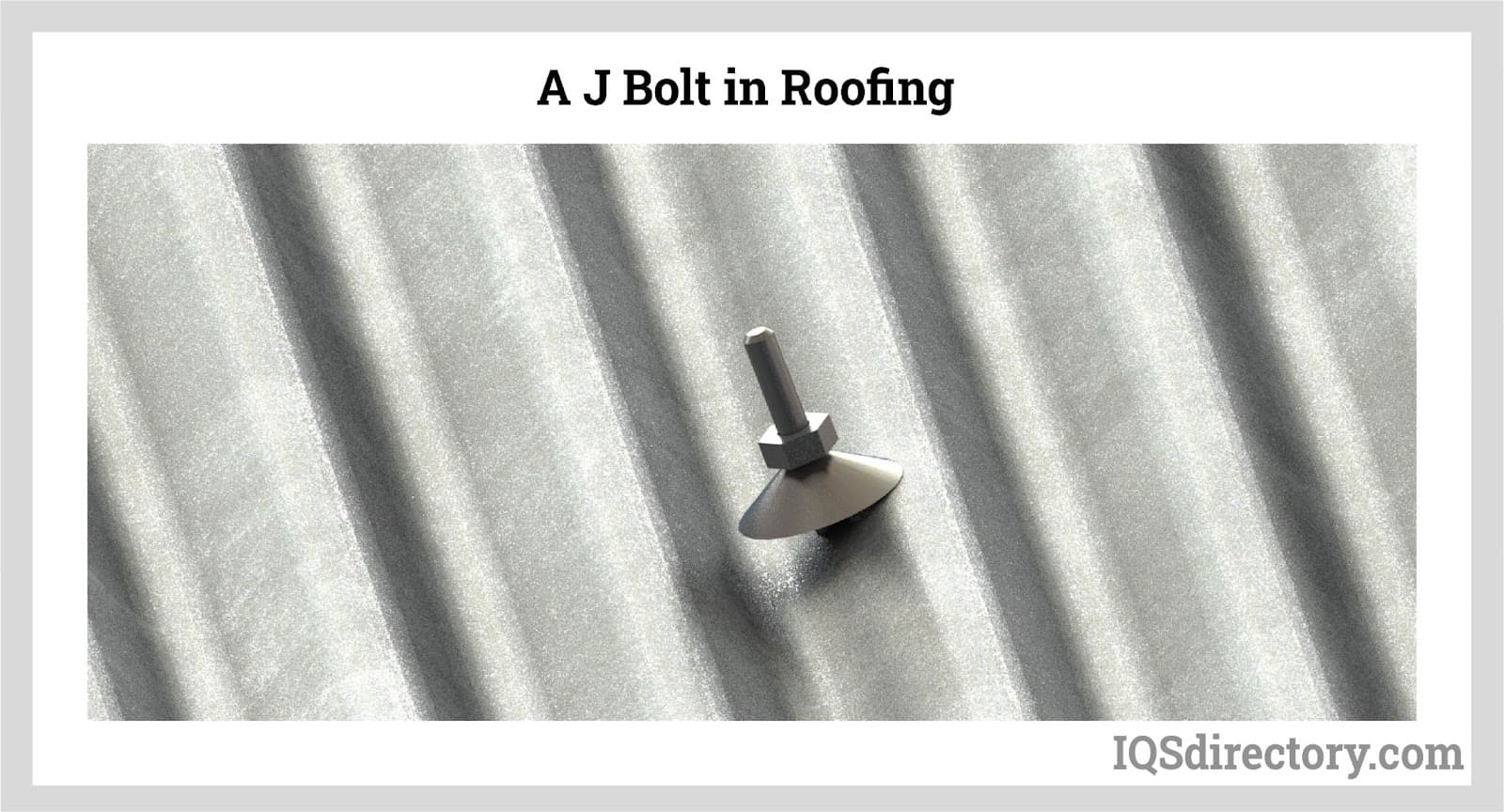

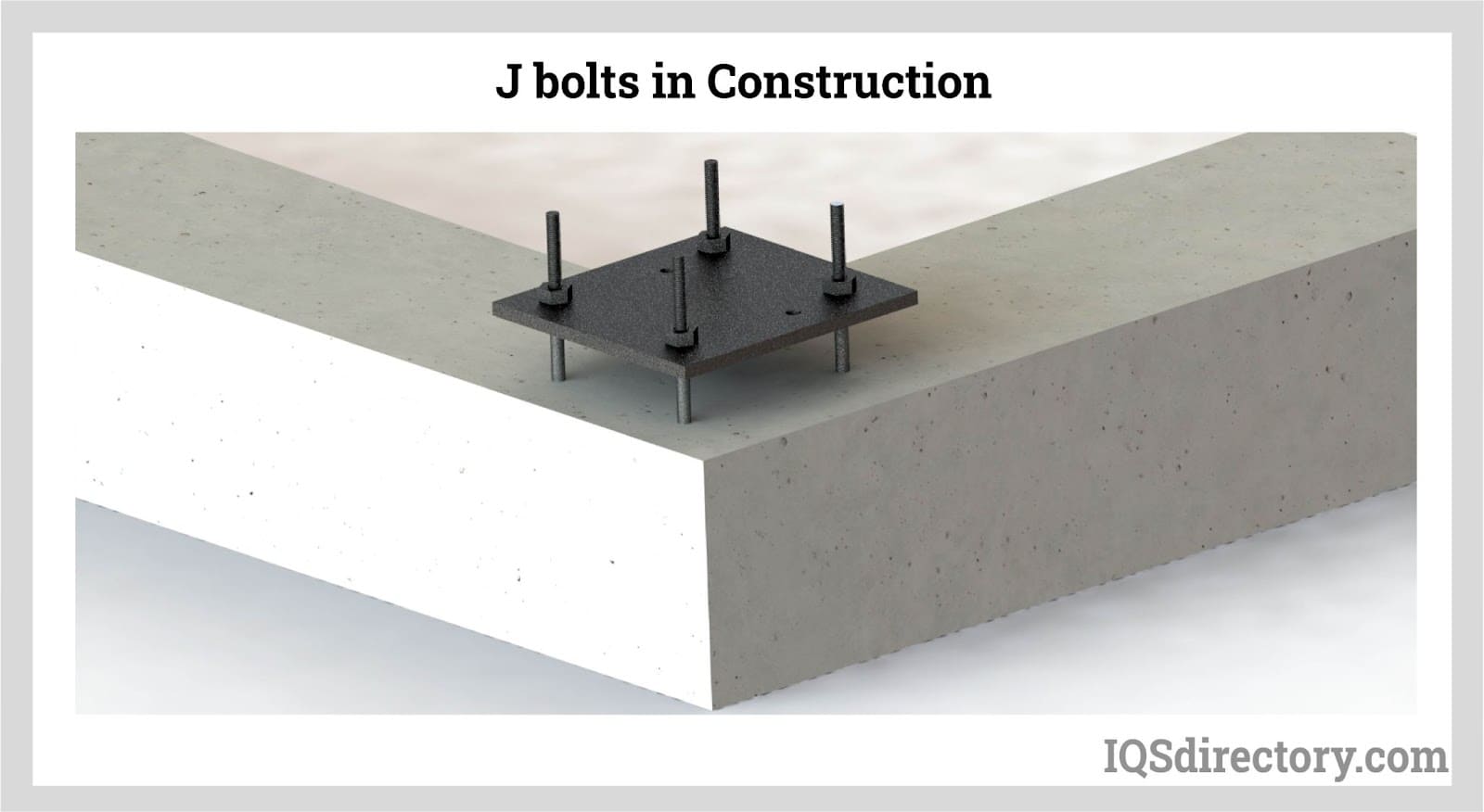

A bolt is a partially-threaded fastener designed to secure objects with the help of a nut. J bolts feature a hook (or J shape) at their bottom to better secure materials to concrete. This form allows a J bolt to attach to rebar implanted in concrete. J bolts are placed into concrete while it is firm, but still wet enough to insert these devices. Roofing applications frequently involve J or hook bolts. When constructing a new structure, construction workers frequently employ these tough fasteners. In addition, homeowners frequently use these fasteners when constructing foundations, garages, or securing walls to concrete.

Manufacturing of J Bolts

J bolts are typically made from stainless steel rods, or zinc-plated steel rods if further strength and rust protection are required. J bolts are produced by cold forging. Under this process, a steel rod is left at room temperature before being pushed under intense pressure through dies to create a desired form. A second die later creates the J-shaped curve after the bolt is cut to the correct length; there is a wide range of available curve angles depending on the thickness of the concrete and the level of fastening support required.

The thread pattern, which is present only on the long, straight part of the bolt, is subsequently pressed using cold forging and high-pressure rollers. Once complete, the J bolt is prepared for use in several situations. The most typical application for J bolts is as anchor bolts, used to secure additional structural elements to concrete. As a result, anchoring is made securely, but flexibility is limited because it is intrinsically difficult to remove a bolt after the concrete has hardened.

Both the J's curve and threaded section can be valuable. The threaded portion of the hook can be screwed into metal, wood, or any other material before being used. Alternatively, the hook can be slid or secured into position, leaving the exposed threaded section for fastening.

Uses of J Bolts

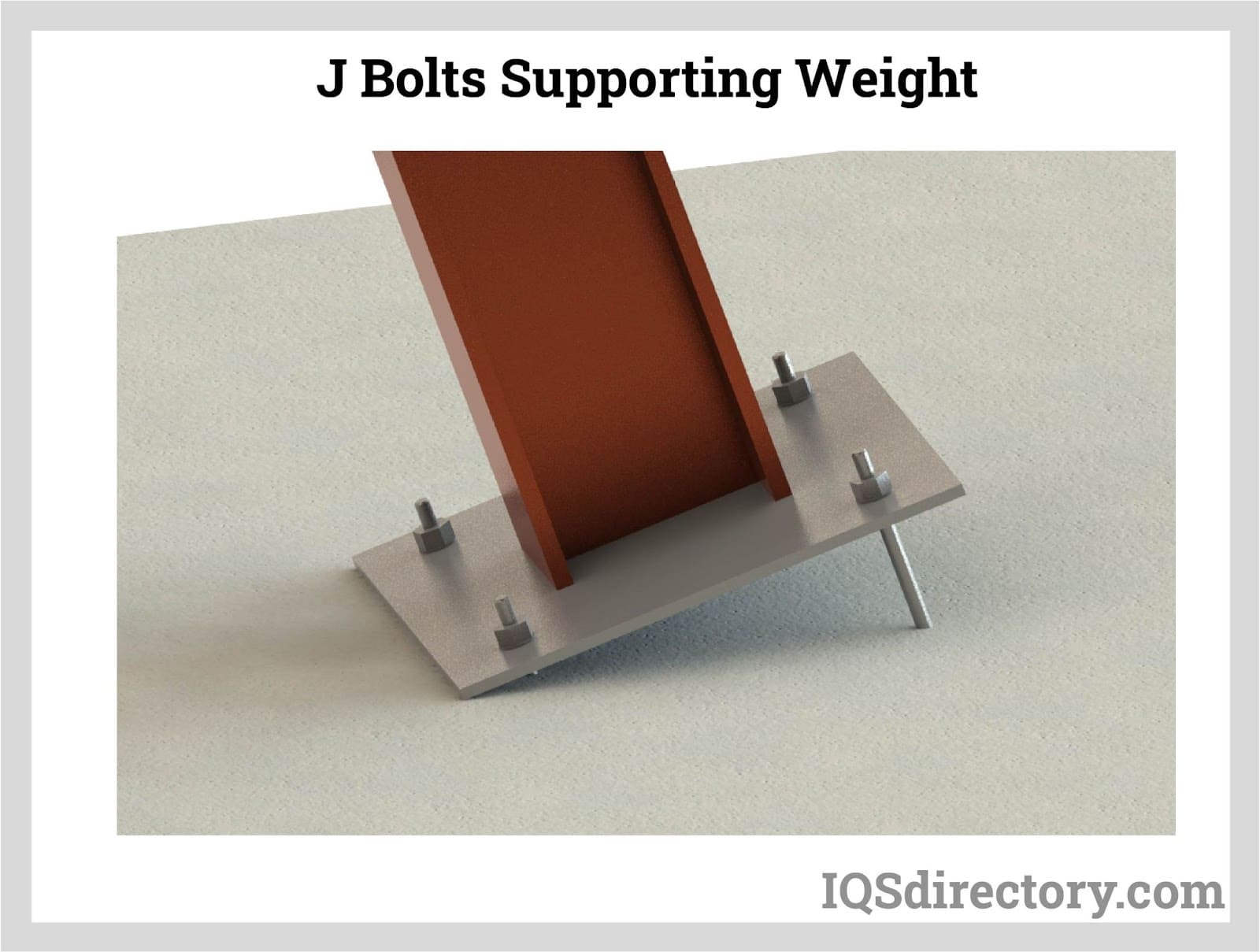

- J bolts are used in a variety of product assemblies, including the internal arrangement of home furnishings with varying weight capacities using springs and hooks, the attachment of sheet metal to wood, the attachment of basic construction materials, metals, and cable forms, the hanging or securing of pipework, tubing, wiring, conduits, or electrical wiring, and even the attachment of different kinds of structures and modules.

- J bolts are excellent for various product assembly needs. They are used by regular producers and assembling companies to attach forms to wooden or metal frames and to support the frame’s weight. J bolts are often threaded on the shaft length. They are utilized in various industry sectors, including automotive applications like fitting tool kits in industrial trucks and pickups, construction, and furniture assembly.

- J bolts are often used in construction, not only in wood but also as an anchor in concrete (typically inserted during the pouring and setting of concrete), but also to attach a range of other metal forms or mechanical fasteners, such as those with hoops, hooks, or eyes.

- Roofing applications frequently involve J or hook bolts. They have a bottom that hooks onto rebar implanted in concrete and threads on top of the fastener. When constructing a new structure, construction workers frequently employ these tough fasteners. Homeowners frequently use these fasteners when constructing foundations, garages, or securing walls to concrete.

Factors to Consider When Using J Bolts

- J bolt hole size: The load-carrying capacity rises as the diameter does.

- Length of the J bolt: The load-bearing capacity increases with the depth of the anchor bolt's embedment in the concrete.

- Environmental circumstances of the building: Will the bolt be exposed to corrosive conditions? Is the material used to construct the bolt able to withstand such factors?

- What is the maximum weight or load that the J bolt can withstand and what load is it expected to bear?

- Type of load: The holding strength of a J bolt gradually declines for vibrating and startling loads.

- What is the expected durability of the material used to create the J bolt?

- What type and thickness of concrete is the J bolt expected to work with?

- What are the fixtures' dimensions and where is the expected placement of a J bolt?

- What is the final product's desired appearance and what impact would a J bolt have on it?

- Are there any J bolt spacing specifications?

- What forces are acting on the whole system where a J bolt is employed (i.e., shear forces which is a force that is projected laterally against something that cannot move)?

Benefits of J Bolts

- J-bolts feature high construction efficiency.

- J-bolts are a simple structure. J-bolts are simple to install, go very deep into material, and make great engagement with the footing.

- J-bolts provide uniform plastering thickness and good anchor effect.

- J-bolts offer better pull-out resistance compared to anchors.

Choosing the Correct J-Bolts Manufacturer

To make sure you have the most productive outcome when purchasing J-Bolts from a J-Bolts Supplier, it is important to compare at least 4 or 5 Manufacturers using our J-Bolts directory. Each J-Bolts Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each J-Bolts business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple J-Bolts companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services