Bolt Products has been a leading supplier of a variety of fasteners, including industrial, mil spec, metric, stainless steel, plastic and high strength fasteners, since 1947. We offer a complete line of high-quality, industrial fastening products to customers around the world.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for bolts tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide...

Manufacturer of fasteners, custom hardware and precision machined components of industrial, aerospace, power generation, petrol-chemical, military, nuclear and commercial applications. Among our industrial bolt offerings are heavy hex bolts, finished hex bolts and oval neck track bolts.

More Shoulder Bolt Manufacturers

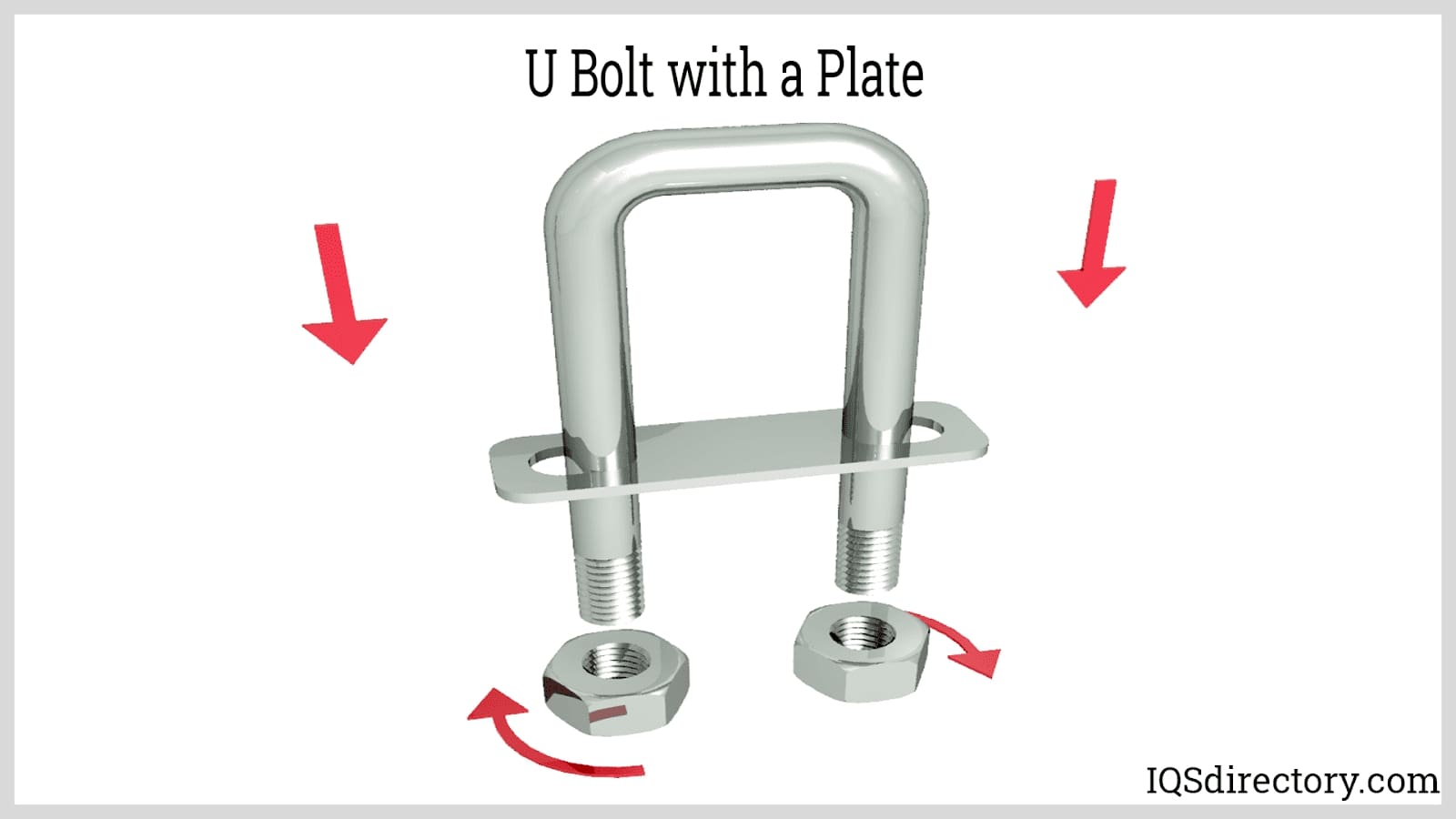

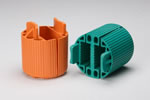

The shoulder in shoulder bolts refers to the unthreaded portion of the shank located directly below the head. This portion of the bolt may be either round or square. Aerospace, automotive and mechanical industries use round shoulder bolts both in finished products and in manufacturing equipment where movement is required.

Square shoulder bolts are used in this settings as well as applications such as woodworking as they resist rotation, providing a more secure clamp than fully threaded screws which may loosen due to vibrations. Beyond the shape differentiation, there are several different types of shoulder bolts. Locating screws, socket shoulder screws, stripper bolts, swing bolts and latch bolts are just a few examples. These bolts are all most commonly made of steel alloys with varying amounts of carbon, manganese, molybdenum, silicon, sulfur and phosphorous additives. These materials offer high tensile strength, corrosion resistance and specific surface qualities that may be enhanced with a number of treatments and finishes. Zinc plating and black oxide finishes are among the most common options.

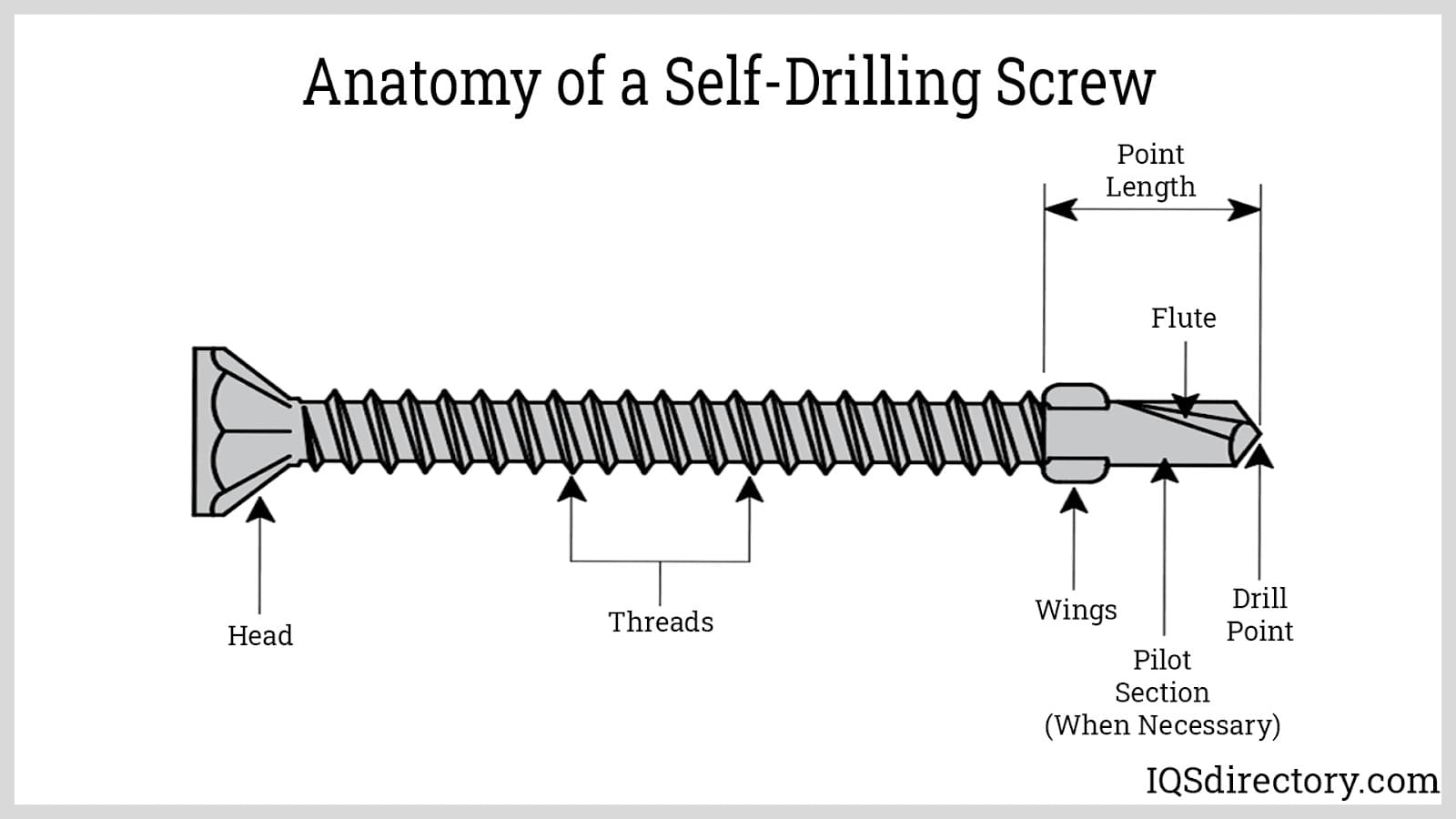

The manufacturing process used to create shoulder bolts is similar to that of other bolt types. A steel wire rod is first heated consistently for an extended period of time and all rust particles are removed. If needed, the metal is coated for added protection. Cold forging is then used to shape the rod at room temperature and the rod is forced through dyes at a high pressure to be shaped into long perfectly round rods. Once cut down to the desired length, a second dye shapes the head of the shoulder bolt which may be square, hexagonal or slotted.

Cold forging using high pressure rollers is then used to press in the thread pattern at the end of the shaft while leaving an unthreaded shoulder. The finished course-pitched shoulder bolt is then ready for use in a variety of applications. It is important to note that the length of this particular type of bolt is a measurement of the unthreaded shank or shoulder rather than the full length of the device. Along with length and material considerations, key size, weight, thread size, shoulder diameter, threaded diameter and head type and diameter should all be considered and selected according to the requirements of the intended use.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services