Bolt Products has been a leading supplier of a variety of fasteners, including industrial, mil spec, metric, stainless steel, plastic and high strength fasteners, since 1947. We offer a complete line of high-quality, industrial fastening products to customers around the world.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Hi-Tech Fasteners, Inc., we specialize in providing comprehensive solutions for bolts tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the field of fastener distribution, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide...

Manufacturer of fasteners, custom hardware and precision machined components of industrial, aerospace, power generation, petrol-chemical, military, nuclear and commercial applications. Among our industrial bolt offerings are heavy hex bolts, finished hex bolts and oval neck track bolts.

More Expansion Bolt Manufacturers

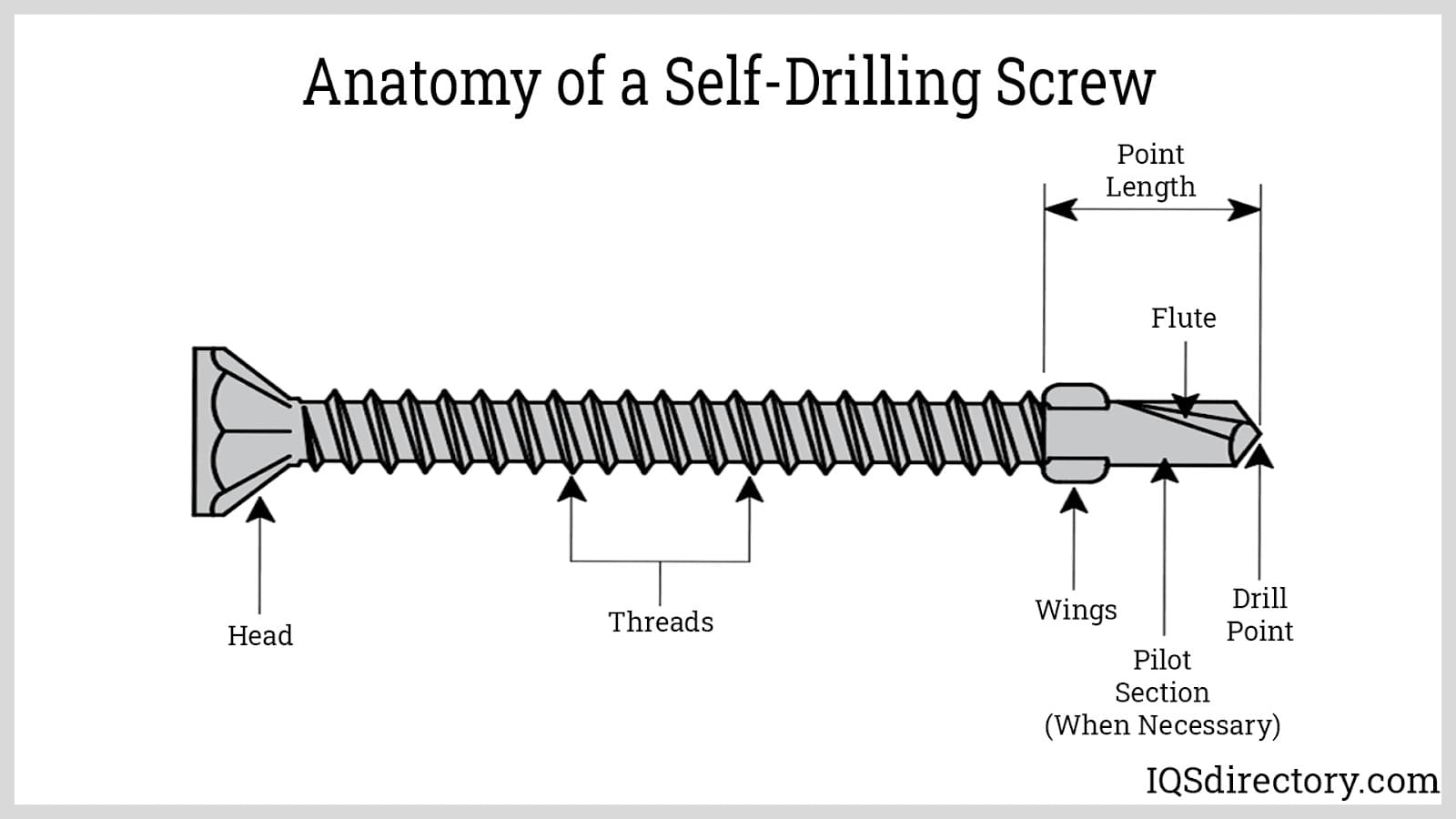

Materials such as concrete and brick are easily damaged by threaded screws and bolts as the treads strip the material rather than biting into it.

Instead of creating cracks and crevices as other bolts do, expansion bolts fill these deformities, which improves aesthetics as well as strengthening the connection. This allows the use of these bolts even in vibratory environments. This reliable anchor bolt can therefore be used in a wide variety of industries. Masonry walls, construction, turbines, motor couplings, gears, mining, seating and sign installation all use expansion bolts to avoid material damage while creating a firm bond.

This bond offers an extreme carrying weight. A relatively small bolt, ¼" for example, can have a pullout weight of up to 2,700 pounds. These carrying weights, measured in tonnage, provide the rating system for expansion bolt manufacturers and suppliers. Bolt length, diameter, materials and configuration should all be carefully considered with regards to the materials to be fastened. These materials should also be considered as poor quality concrete will crumble under such extreme weights no matter the type or class of bolt.

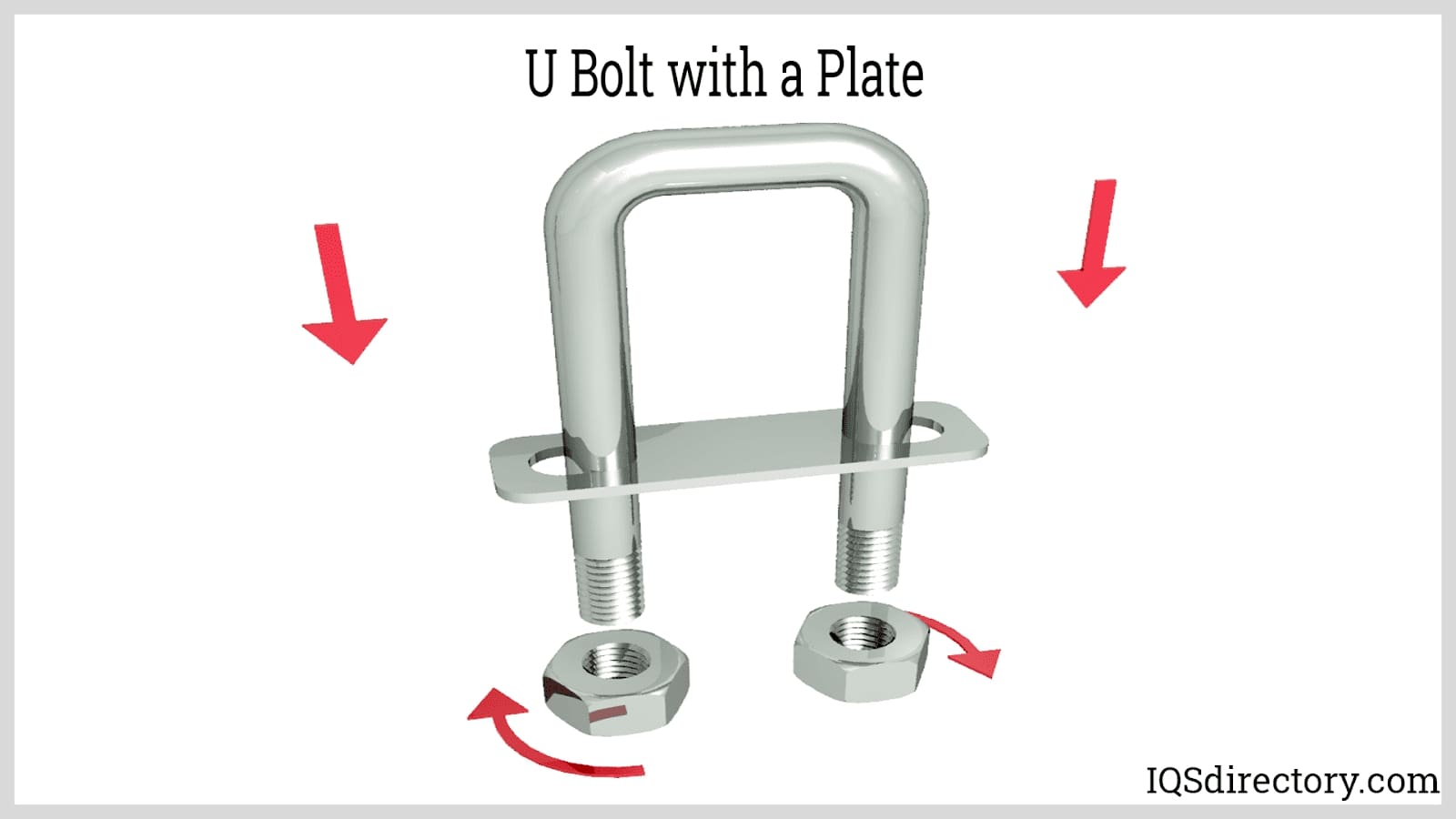

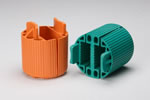

Each bolt system has three basic parts, the bolt, nut and sleeve, which may be assembled in a number of configurations. In the bolt-lead sleeve-tapered nut set up the entire mechanism is inserted into a pre-drilled hole and the tapered nut is drawn back towards the head to compress and expand the lead sleeve. The bolt-lead sleeve-metal cone-nut functions in the same manner though the metal cone is driven into the sleeve causing expansion rather than the nut. The tapered bolt-lead sleeve-metal cone-nut configuration is similar in assembly although the tapered bolt is responsible for expansion rather than the nut or the metal cone.

In any assemblage the bolt, nut and cone, if present, are made of steel alloys which offer strength and corrosion resistance. Cadmium and zinc plating are common finishes for bolts that may face continual exposure to water and other environmental elements. While each of these components is integral to the bolt design, the lead sleeve is the crucial element of the expansion bolt. Lead is a malleable substance. When compressed it easily fills the drilled spaces as well as any surrounding cracks or pores. This creates multiple points of attachment while minimizing the risk of cracking or shattering the anchoring material.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services