Our company has manufacturing experiences dating back to 1970 and over the years we have grown into an international supplier of bolts.

With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

As a distributor, Blue Ribbon Fastener offers a variety of industrial bolts including carriage bolts, elevator bolts, lag bolts, stripper bolts, plow bolts, hanger bolts, elevator bolts, stud bolts and toggle bolts. Custom and standard products are available in virtually any material.

Here at Eagle Fastener Corporation, we stand proudly as a trusted leader in the realm of bolts, offering a comprehensive array of products, services, and capabilities to cater to the diverse needs of our esteemed clientele. With an unwavering commitment to excellence and extensive expertise in bolt manufacturing, we are poised to deliver innovative solutions that excel in quality, reliability,...

Connect With Recommended Industrial Bolt Suppliers

Provide us with your project specifications, and we’ll connect you with our network of qualified plating & coating suppliers who can give you a free proposal. Our team has been manually sourcing and curating the best U.S. manufacturers for over 20 years.

Request for QuoteWe're the #1 destination for finding U.S. Manufacturers

More Industrial Bolt Manufacturers

Bolts are a common and essential part of modern construction and manufacturing. They are used to securely join two or more objects together and are designed to withstand high-stress loads. Bolts have been around for centuries, with the earliest known bolts dating back to ancient Greece. Over time, bolts have evolved to become an essential part of modern construction and manufacturing. Bolts come in various shapes and sizes, each designed for specific applications.

Materials Used for Bolts

Bolts can be made from different materials, including steel, stainless steel, titanium, and brass. Steel bolts are the most commonly used bolts because of their strength and durability. Stainless steel bolts are preferred when corrosion resistance is essential. Titanium bolts are used in applications where high strength and low weight are required, such as in aerospace applications. Brass bolts are used when electrical conductivity is essential.

Design and Application Differences of Bolts

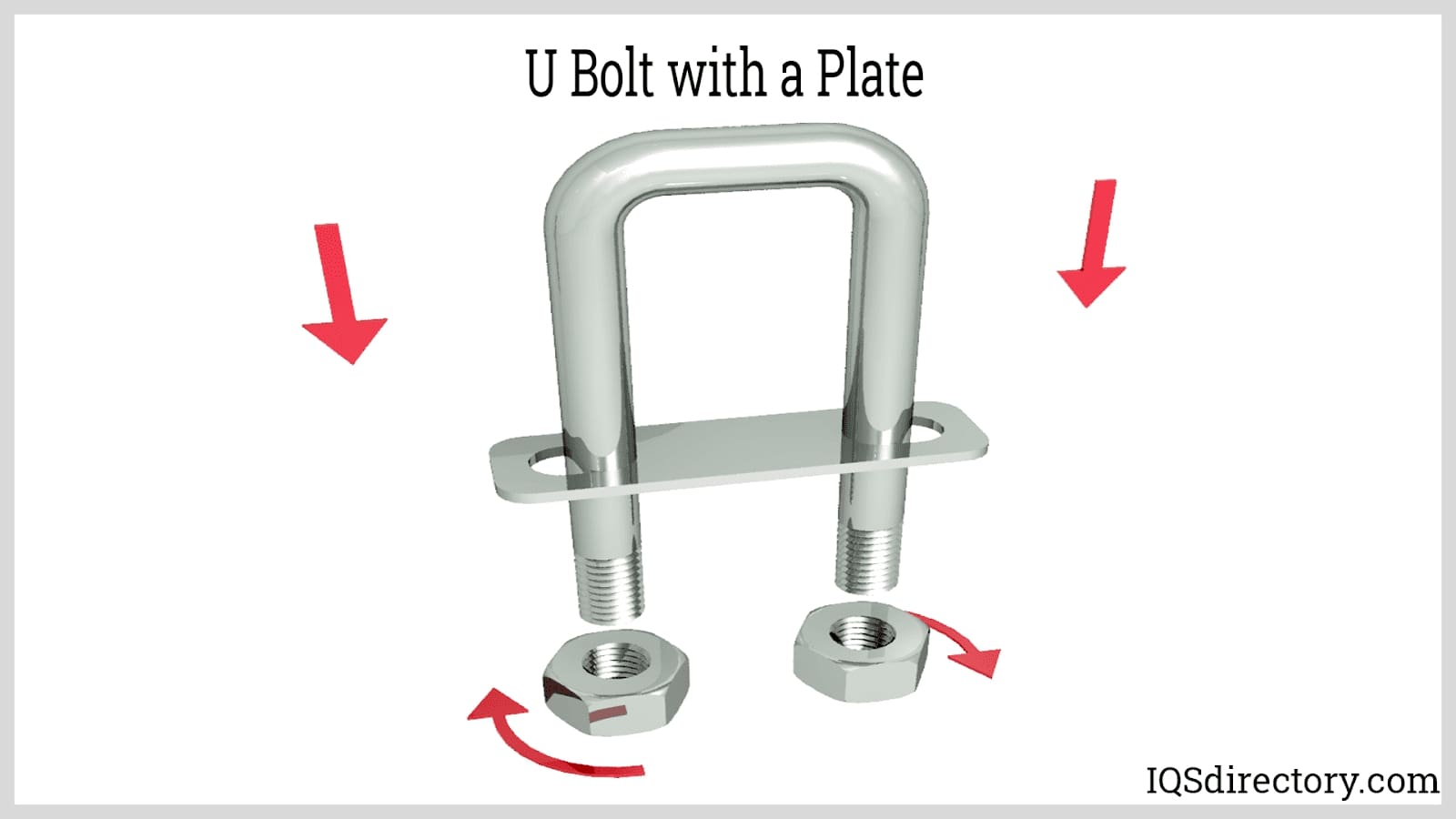

There are different types of bolts, including anchor bolts, carriage bolts, expansion bolts, eye bolts, hex bolts, industrial bolts, J bolts, lag bolts, metric bolts, shoulder bolts, stud bolts, thru-bolts, and U bolts. Each type of bolt has a different design and application. For example, anchor bolts are used to anchor structures to concrete, while carriage bolts are commonly used in wood construction. Hex bolts are used in general construction, while shoulder bolts are used in rotating applications.

Factors when Choosing Bolts

While bolts are strong and reliable, they do have some limitations. Bolts can corrode over time, leading to failure. Additionally, bolts may fail under high stress loads, leading to structural failure. However, these limitations can be overcome through proper selection of materials and designs.

Benefits Provided by Bolts

Bolts provide a wide range of benefits, some of which are listed below:

Strength and Stability

Bolts provide a secure and stable connection between two or more objects, making them an ideal choice for applications where strength is essential. They can withstand high levels of tension and compression without breaking or deforming.

Easy to Install

Bolts are relatively easy to install and require only a few tools to tighten them securely. This makes them a popular choice for DIY projects and small-scale construction projects.

Versatility

Bolts are available in a wide range of sizes, shapes, and materials, making them a versatile fastener option for a wide range of applications. Bolts provide a certain level of adjustability, which can be useful in applications where precise alignment is required

Cost-Effective

Bolts are a cost-effective fastener option, especially when compared to other options such as welding or riveting. They require less labor and specialized equipment, which can result in significant cost savings. Bolts are a reusable fastener option, which can be beneficial in applications where disassembly and reassembly is required.

Corrosion Resistance

Bolts can be made from materials that are resistant to corrosion, such as stainless steel, which makes them an ideal choice for outdoor or marine applications.

Aesthetic Appeal

Bolts can be customized to match the aesthetic of the application, which can be important in applications where appearance is a consideration.

Applications of Bolts

Bolts are used in a wide range of applications, some of which are listed below:

Construction

Bolts are used extensively in the construction industry to join steel and concrete structures. They are commonly used in steel framing, bridge construction, and building foundations.

Automotive Manufacturing

Bolts are used in automotive manufacturing to secure various components of a vehicle, such as the engine and transmission.

Aerospace

Bolts are used extensively in aerospace applications, where they are used to secure critical components and structures. They must meet strict performance requirements and are often made of lightweight materials such as titanium.

Manufacturing Machinery

Bolts are used to manufacture equipment to connect various components together. They are also used to mount equipment to a floor or wall. Bolts are used to manufacture electrical and electronic equipment to mount components to a chassis or enclosure. They are often made of non-conductive materials to prevent electrical shorts.

Marine

Bolts are used in the marine industry to secure various components of a ship, such as the engine and propeller. They must be made of materials that can withstand the corrosive effects of saltwater.

Agriculture

Bolts are used in agriculture to secure components of machinery such as tractors, cultivators, and planters. They are also used to anchor structures such as grain bins and silos.

Furniture Manufacturing

Bolts are to manufacture furniture to secure various components such as table legs and chair frames.

Sporting Equipment

Bolts are to manufacture sporting equipment such as bicycles, skateboards, and snowboards to secure various components together.

Medical Equipment

Bolts are to manufacture medical equipment to secure various components together. They are often made of materials that can withstand high temperatures and sterilization processes.

Choosing The Right Bolt Supplier

To ensure you have the most constructive outcome when purchasing bolts from a bolt supplier, it is important to compare several companies using our directory of bolt suppliers. Each bolt supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each bolt company’s business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to communicate with multiple bolt companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services